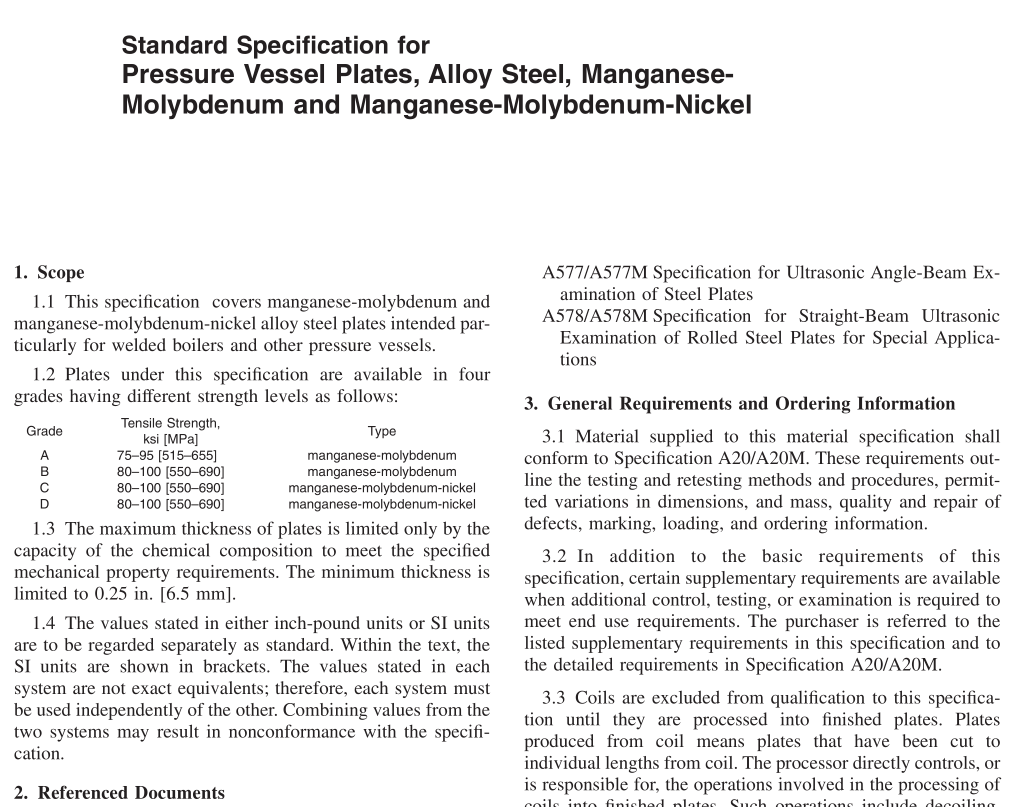

ASME SA312:2013 pdf free download Standard Specification for Pressure Vessel Plates, Alloy Steel, Manganese- Molybdenum and Manganese-Molybdenum-Nickel

3.1.2 Name of product, bolts or studs; and bolt headstyle, that is,hex or heavy hex,

3.1.3 Grade, that is,A, or B. If no grade is specified,Grade A is furnished.

3.1.4Quantities (number of pieces by size includ-ing nuts),

3.1.5 Fastener size and length,

3.1.6 Washers – Quantity and size (separate frombolts),

3.1.7 Zinc Coating — Specify the zinc-coating pro-cess required, for example, hot-dip,mechanically depos-ited, or no preference (see 4.5).

3.1.8 Other Firishes — Specify other protective fin-ish,if required.

3.1.9Specify if inspection at point of manufactureis required,

3.1.10 Specify if certified test report is required (see8.2), and

3.1.11Specify additional testing (8.3) or specialrequirements.

3.1.12 For establishment of a part identifying system,see ASME B18.24.

4. Materials and Manufacture

4.1Steel for bolts and studs shall be made by theopenhearth, basic-oxygen, or electric-furnace process.4.2 Bolts shall be produced by hot or cold forging ofthe heads or machining from bar stock.

4.3 Heat Treatnent:

4.3.1Cold headed fasteners with head configurationsother than hex shall be stress relief annealed.

4.3.2Stress relieving of hex head fasteners shall beat the manufacturer’s option.

4.4 Bolt and stud threads shall be rolled or cut.

4.5 Zinc Coatings, Hot-Dip and MechanicallyDeposited:

4.5.1 When zinc-coated fasteners are required,thepurchaser shall specify the zinc-coating process, for exam-ple hot dip, mechanically deposited, or no preference.

4.5.2 When hot-dip is specified, the fasteners shallbe zinc-coated by the hot-dip process in accordance withthe requirements of Specification F 2329.

4.5.3 When mechanically deposited is specified, thefasteners shall be zinc-coated by the mechanical-depositionprocess in accordance with the requirements of Class 55of Specification B 695.

4.5.4When no preference is specified, the suppliermay furnish either a hot-dip zinc coating in accordancewith Specification F 2329,or a mechanically depositedzinc coating in accordance with Specification B 695, Class55.Threaded components (bolts and nuts) shall be coatedby the same zinc-coating process and the supplier’s optionis limited to one process per item with no mixed processesin a lot.

5. Chemical Composition

5.1Grade A and B bolts and studs shall have a heatanalysis conforming to the requirements specified inTable 1 based on the steel producer’s heat analysis.

5.2The purchaser shall have the option of conductingproduct analyses on finished bolts in each lot, which shallconform to the product analysis specified in Table 1.5.3In case of conflict or for referee purposes,theproduct analysis shall take precedence.

5.4 Bolts and studs are customarily furnished fromstock,in which case individual heats of steel cannot beidentified.

5.5Application of heats of steel to which bismuth,selenium, tellurium,or lead has been intentionally adldedshall not be permitted for Grade B bolts and studs.

5.6Chemical analyses shall be performed in accor-dance with Test Methods,Practices,and TerminologyA 751.

6. Mechanical Properties

6.1Grades A and B bolts and studs shall conform tothe hardness specified in Table 2.

6.2Grade A and B bolts and studs 1! in. in diameteror less,other than those excepted in 6.4,shall be testedfull size and shall conform to the requirements for tensilestrength specified in Table 3.

6.3Grade A and B bolts and studs larger than 1! in.in diameter, other than those excepted in 6.4, shall prefera-bly be tested full size and when equipment of sufficientcapacity is available and shall conform to the requirementsfor tensile strength specified in Table 3. When equipmentof sufficient capacity for full-size bolt testing is not avail-able, or when the length of the bolt makes full-size testingimpractical, machined specimens shall be tested and shallconform to the requirements specified in Table 4.

ASME SA312:2013 pdf free download