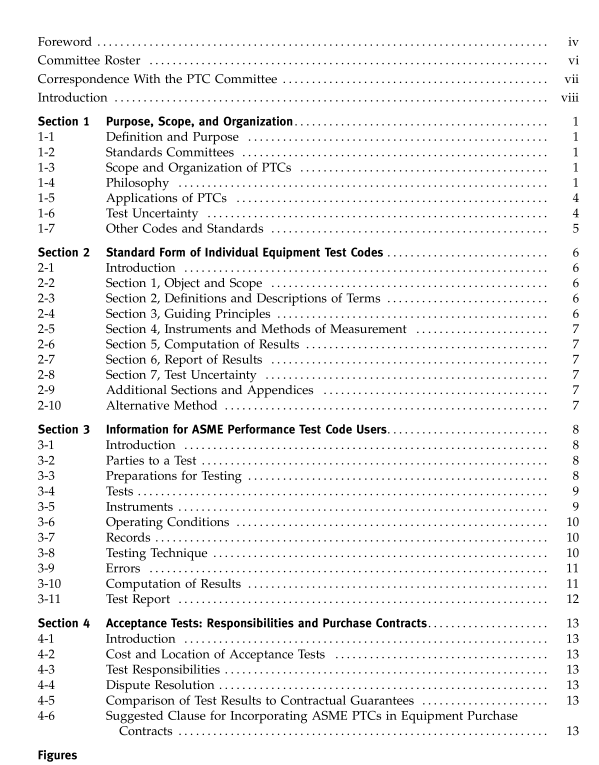

ASME PTC 1:2015 pdf free download General Instructions Performance Test Codes

1-1 DEFINITION AND PURPOSE

ASME Performance Test Codes (PTCs) provide uni-form rules and procedures for the planning, preparation,execution,and reporting of performance test results.Test results provide numerical characteristics to the per-formance of equipment, systems, and plants beingtested. Throughout ASME PTC1, when the term”equipment” is used with reference to the object of aperformance test, it can refer to specific equipment,systems, or to entire plants.

1-2STANDARDS COMMITTEES

ASME PTCs are developed by technical committeesthat are governed, organized, and appointed by thePerformance Test Codes Supervisory Committee underthe auspices of the Board on Standardization and

Testing. Each code-writing committee is organized toinclude representatives of several interest groups. Thequalifications of each member of a code-writing commit-

tee are subject to examination and approval by theSupervisory Committee. Members of the code-writingcommittees are highly qualified, technically competentprofessionals,generally members of ASME, who haveexpertise in the field or in an area of expertise neededby the committee, such as special instrumentation. Theypresent their views on matters under consideration asmembers of a learned profession, not as representativesof employers or special interest groups.

1-3 sCOPE AND ORGANIZATION OF PTCs

Most ASME PTCs are applicable to a specified typeof equipment defined by the Code. There may be severalsubcategories of equipment covered by a single code.Types of equipment to which PTCs apply can be classi-fied into five broad categories.

(a) power production

(b) combustion and heat transfer(c) fluid handling

(d) emission

(e) instruments,apparatus,and other supplementaldocuments

The quantities that characterize performance aredefined in each code for the equipment within its scope.Absolute performance characteristics determined byadherence to a PTC can be evaluated as compared todesign or predicted characteristics, to previous testresults, or they can be used to benchmark or ascertainperformance at a particular time.

Some PTCs are written as general documents for refer-ence in support of the equipment PTCs.These can beconsidered as technical reference material for the equip-ment codes.Three types of reference codes exist.

The first type covers instrumentation used in the mea-surement of thermodynamic or process fluid parame-ters,such as pressure, temperature, flow, and shaftpower. Such individual codes referring to process orthermodynamic quantities are known as PerformanceTest Code Instruments and Apparatus Supplements.They are supplementary to the information on manda-tory instrumentation requirements contained in theequipment codes. Instrumentation information in equip-ment test codes supersedes the information given inthese supplements, but otherwise these supplementsshould be incorporated by reference in equipment testcodes where deemed appropriate by the committee.The second type covers guidance and reference infor-mation. It currently consists of PTC 1,GeneralInstructions, and PTC2, Definitions and values. PTC2contains standards for terms, units, values of constants,and technical nomenclature.

The third type addresses how to analyze the uncer-tainties associated with measurement of all primaryparameters to develop overall test uncertainty. It cur-rently consists of PTC 19.1,Test Uncertainty.

Figures 1-3-1 and 1-3-2 show the organization ofASME Performance Test Code categories.

1-4PHILOSOPHY

PTCs provide guidelines for test procedures that yieldresults of the highest level of accuracy based on currentengineering knowledge, taking into account test costsand the value of information obtained from testing. Pre-cision and reliability of test results must underlie all

ASME PTC 1:2015 pdf free download