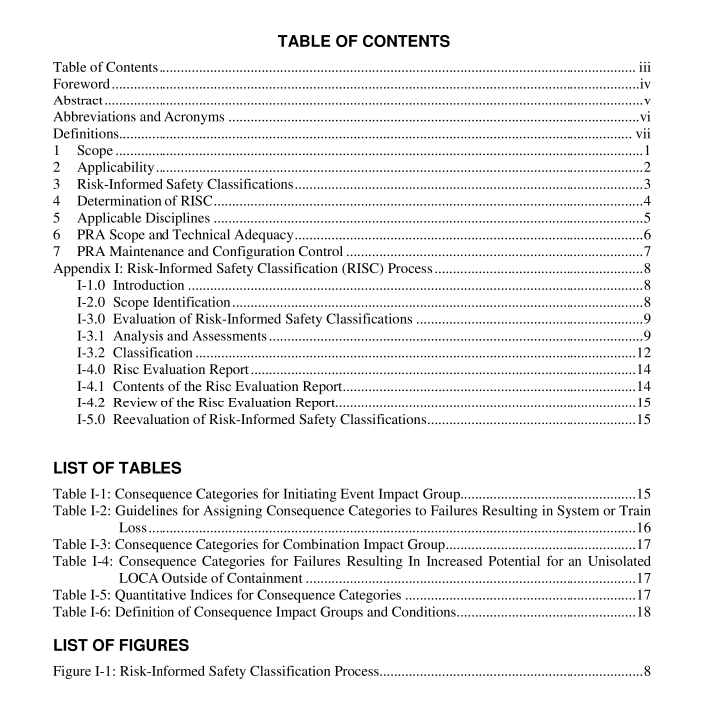

ASME NTB-5:2022 pdf free download Guidance for Determination of Risk-Informed Safety Classification for Light Water Reactor Nuclear Facility Pressure Retaining Components

I-3.0 EVALUATION OF RISK-INFORMED SAFETY CLASSIFICATIONS

All pressure-retaining items in a piping system should be evaluated by defining piping segments that aregrouped based on similar conditional consequence (i.e., given failure of the piping segment). Toaccomplish this grouping, the direct effects and indirect effects should be assessed for each piping segment.A Consequence Category for each piping segment is determined from the Failure Modes and EffectsAnalysis and Impact Group Assessment as defined in I-3.1.1,and 1-3.1.2,respectively. The failureconsequence can be quantified using a PRA(s) meeting the guidance of Section 5 of this document.Throughout the evaluations of 1-3.0, 1-3.1, and I-3.2, credit may be taken for plant features and operatoractions to the extent these would not be affected by failure of the piping segment under consideration.When crediting operator action,the likelihood for success and failure needs to be determined and thescenario that results in the highest consequence ranking should be used%.To take credit for operator actions,the following features should be provided:

(a) An alarm or other system feature to provide clear indication of failure,

(b) Equipment activated to recover from the condition must not be affected by the failure,(c)Time duration and resources are sufficient to perform operator action,

(d)Plant procedures to define operator actions, and

(e) Operator training in the procedures.

1-3.1ANALYSIS AND ASSESSMENTS

1-3.1.1 Failure Modes and Effects Analysis(FMEA)

Potential failure modes for each system or piping segment should be identified, and their effects should beevaluated. This evaluation should consider the following:

(a) Pressure Boundary Failure Size. The consequence analysis should be performed for a spectrum of

pressure boundary failure sizes from small to large.The failure size that results in the highestconsequence ranking should be used.

In lieu of this, a small leak may be assumed provided it can be ensured that the possibility of a largepressure boundary failure has been precluded (e.g., presence of a flow restricting orifice).

(b) Isolability of the Break. A break can be automatically isolated by a check valve, a closed isolation

valve, or an isolation valve that closes on a given signal. In lieu of automatic isolation, operatoraction may be credited consistent with I-3.0.

(c) Indirect Effects.These include spatial effects (e.g., pipe whip, flooding) and loss-of inventory

effects (e.g., draining of a tank).

(d) Initiating Events. Applicable initiating events are identified using a list of initiating events from

the plant-specific PRA and the plant design basis.For system failures or piping segments failuresthat are not modeled, either explicitly or implicitly, in the plant-specific PRA, analysis might berequired to identify applicable initiating events (i.e. a representative failure effect is not modeledin the PRA).This analysis should be conducted in accordance with this Appendix.

(e) System Impact or Recovery.These are the means of detecting a failure,and the Technical

Specifications associated with the system and other affected systems. Possible automatic andoperator actions to prevent a loss of system function should be evaluated consistent with 1-3.0.

(f) System Redundancy. The existence of redundancy for accident mitigation purposes should be

considered.

(g) System Configuration. The consequence evaluation and ranking is organized into four basic

consequence impact groups as discussed in I-3.1.2.The three corresponding system configurationsfor these impact groups are defined in Table l-6.

1-3.1.2 lmpact Group Assessment

The results of the FMEA evaluation for each piping system, or portion thereof, should be classified intoone of three core damage impact groups: initiating event, system, or combination. In addition,failuresshould also be evaluated for their importance relative to containment performance. Each piping system, orportion thereof, should be partitioned such that failure of each partition can cause an initiating event, disablea system without causing an initiating event, or cause an initiating event and disable a system, train or loop.The consequence category assignment(high, medium, low, or none) for each piping segment should be thehighest category as determined in accordance with (a) through (f) below.

(a) Initiating Event (IE)Impact Group Assessment. When the postulated failure results in only an

initiating event (e.g., loss of feedwater, reactor trip), the consequence should be classified into oneof four consequence categories: high, medium, low, or none. The initiating event category shouldbe assigned according to the following:

(1) The initiating event should be placed in one of the Design Basis Event Categories in Table I-

1. All applicable design basis events previously analyzed in the preliminary or final safetyanalysis report (PSAR/FSAR) or PRA should be included.

(2) Breaks that cause an initiating event classified as Category I (routine operation) need not be

considered in this analysis.

(3) For piping segment breaks that result in Category ll (Anticipated Event),Category lII

(Infrequent Event), or Category IV (Limiting Fault or Accident), the consequence categoryshould be assigned to the initiating event according to the conditional core damage probability(CCDP) criteria specified in Table I-5.Differences in the consequence rank between the useof Table 1-1 and Table 1-5 should be reviewed,justified and documented or the higherconsequence rank assigned. The quantitative index for the initiating event impact group is theratio of the core damage frequency due to the initiating event to the frequency for that initiatingevent.

(b) System Impact Group Assessment. The consequence category of a failure that does not cause an

initiating event, but degrades or fails a system essential to prevention of core damage, should beevaluated. This evaluation should include all safety functions supported by the piping segment aswell as all safety functions impacted by failure of the piping segment. This evaluation should bebased on the following:

(1) Frequency of challenge that determines how often the affected function of the system is called

upon.This corresponds to the frequency of events that require the system operation.

(2) Number of backup systems (portions of systems,trains, or loops) available, which determines

how many unaffected systems (portions of systems,trains, or loops) are available to performthe same mitigating function as the degraded or failed systems.

ASME NTB-5:2022 pdf free download