ASME HST-4:2016 pdf free download Performance Standard for Overhead Electric Wire Rope Hoists

SECTION 4-1.1 GENERAL

Al1 equipment selected in accordance with thisStandard is designed to perform satisfactorily wheninstalled, inspected,tested,operated, and maintainedin accordance with Chapters 16-1 through 16-4 ofASME B30.16 and used within the rated load and hoistduty service classification.All equipment shall providespeeds, lifts,and headroom in accordance with the man-ufacturer’s specifications, or to specifications agreedupon by the manufacturer and user.

SECTION 4-1.2 HOIST DUTY SERVICE

CLASSIFICATION

4-1.2.1 General Considerations

Service conditions have an important influence on theperformance of wearing parts of a hoist such as gears,bearings, rope, sheaves, electrical equipment, brake lin-ings,load- and lift-limit devices,and wheels. Carefulconsideration of the hoist duty service classificationsdescribed in this section will enable the user to evaluatethe application and to obtain a hoist designed for opti-mum performance and minimum maintenance.If doubtexists regarding hoist selection, the hoist supplier shouldbe consulted. Many factors enter into the selection ofthe proper hoist to perform a given function. Hoistingequipment consists of both mechanical and electricalcomponents, and both must be considered when analyz-ing the service the hoist must perform.

The factors that influence the performance of any hoistinclude the following:

(a) Load Distribution. The actual distribution or pro-portion of full and partial loads to be handled by theequipment, including lifting devices, has an importanteffect on the life of power transmission components.For example, ball bearing life generally varies inverselyaccording to the cube of the load. A 2-ton (1 814.4-kg)hoist,operated at a mean effective load of 1 ton(907.2 kg), will have a ball bearing life eight times thatof the same hoist used steadily at its rated load.

(b)Operational Time. Operational time is the total run-ning time of the hoist per hour or per work period.(c) Work Distribution. This is determined by whetherthe operational time is uniformly distributed over thework period or concentrated in a short time span.Workdistribution generally does not appreciably affectmechanical wear but does materially affect the electrical components such as motors, brakes,and controls. Forexample, a hoist motor designed to operate 15 min outof each hour of an 8-hr shift cannot handle 2 hr of steadyrun and 6 hr of idle time even though either conditiononly requires 2 hr of operational time per 8-hr shift.(d) Nunber of Starts and Stops. This directly affects allelectromechanical devices, such as motors,contactors,brakes, and solenoids.

(e)Repetitive Long Lowering Operations. Such opera-tions generate heat in control braking means.

(f)Environmental Conditions. Such conditions includeambient temperature and the presence of dust, moisture,corrosive fumes,etc. Hoist equipment is designed tooperate in ambient temperatures between 0°F and 104F(-18C and 40°C) and in atmospheres reasonably freefrom dust, moisture, and corrosive fumes unless other-wise specified.

4-1.2.2 Hazardous Locations

When hoists are used in hazardous locations asdefined by ANSI/NFPA 70 or other special codes, modi-fications or additional precautions not covered by thisStandard may be required. In these locations, only hoistsdesigned in a manner suitable for the conditions encoun-tered shall be used.

4-1.2.3 Duty Classification

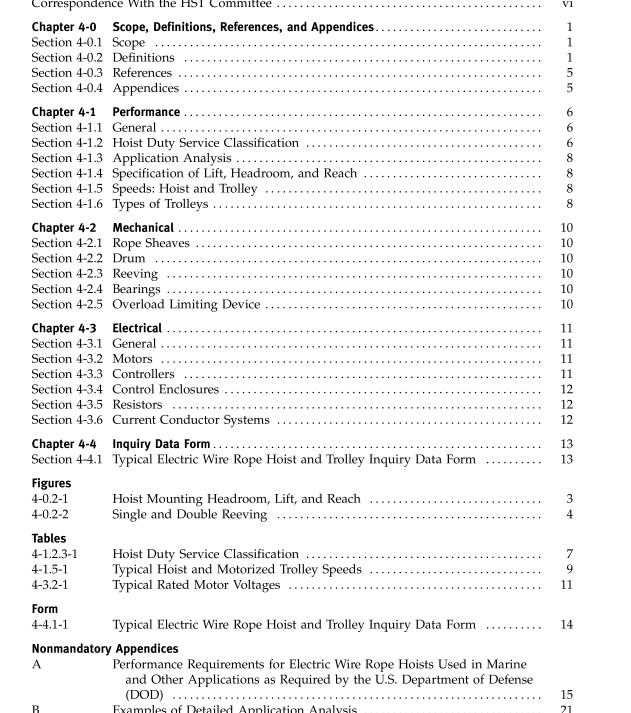

While all the factors listed in para.4-1.2.1 must beconsidered in selecting the proper class of hoist, mostindustrial applications, having randomly distributedloads or uniform loads up to 65% of rated load handledperiodically throughout the work period,can be general-ized according to the type of workshop or area of appli-cation.Listed in Col. i of Table 4-1.2.3-1 are the fiveduty classes that have been established for electric wirerope hoists. In Col. 2 are listed typical areas of applica-tion where each class can normally be applied.

The majority of hoist applications fall into one of thethree categories H1, H2, or H3, and the use of the gener-alized descriptions in Co1.2 of Table 4-1.2.3-1 for selec-tion of the hoist will be adequate.

(a)Operational Time Ratings. If in doubt as to therequired duty classification for an application, refer tothe data in Cols. 3 through 6 of ‘Table 4-1.2.3-1,whichshow the operational time ratings for each class.

(1)uniformly Distributed Work Periods

(-a) Maximun On Time, min/hr. The maximumrunning time in minutes per hour permitted for the duty

ASME HST-4:2016 pdf free download