ASME EA-4:2010 pdf free download Energy Assessment for Compressed Air Systems

Assessments involve collecting and analyzing systemdesign,operation, energy use,and performance dataand identifying energy performance improvement op-portunities for system optimization.An assessment mayalso include additional information, such as recommen-dations for improving resource utilization, reducing perunit production cost,reducing lifecycle costs,and im-proving environmental performance related to the as-sessed system(s).Assessment activities include, but arenot limited to, engaging facility personnel and provid-ing information about the assessment process; collectingand analyzing data on system design, operation, energyuse, and performance; identifying energy performanceimprovement opportunities; and making recommenda-tions for system improvement and implementation ina written report. This report should document systemdesign; quantify energy operation and performancedata; document the assessment process; show results,recommendations, and energy savings projections; andimprove facility personnel’s understanding of systemenergy use and operation.

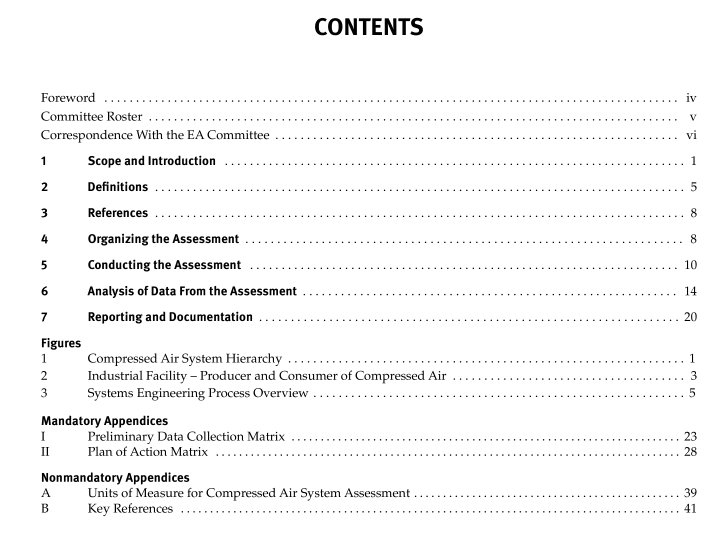

This Standard sets requirements for

(a) organizing and conducting a compressed air sys-tem assessment

(b) analyzing the data from the assessment

(c) reporting and documentation of assessment findingsWhen contracting for assessment services, plant per-sonnel may use the Standard to define and communicatetheir desired scope of assessment activity to third partycontractors or consultants

1.2Limitations

This Standard does not provide guidance on how toperform an assessment for compressed air systems butsets the requirements that need to be met during the as-sessment. For additional assistance, see the companionASME Guidance for ASME EA-4 Energy Assessment forCompressed Air Systems on how to apply this Standard.(a)This Standard does not specify how to design acompressed air system.

bj This Standard does not specify the qualificationsand expertise required of the person using the Standard.(c)This Standard does not specify how to implementthe recommendations developed during the assessmentbut does include recommendations for implementationactivities.

(d)This Standard does not specify how to measureand validate the energy savings that result from imple-menting assessment recommendations.

(e) This Standard does not specify how to calibrate testequipment used during the assessment.

(fThis Standard does not specify how to estimate theimplementation cost or conduct financial analysis forrecommendations developed during the assessment.(g)This Standard does not specify specific steps re-quired for safe operation of equipment during the assess-ment. The plant personnel in charge of normal operationof the equipment are responsible for ensuring that it isoperated safely during the data collection phase of theassessment.

(h)For outside individuals working in a private orpublicly owned company facility,issues of intellectualproperty,confidentiality, and safety shall be addressedbefore beginning an assessment. While the importanceof satisfying these requirements and related issues is ac-knowledged, they are not addressed in this Standard

1.3 Introduction – Using the System Assessment

Standard

Industrial facilities use compressed air as an essentialenergy source to power tools or machines and for pro-cess applications.Characteristics of compressed air, suchas responsiveness and safety , make it an effective and de-sirable means of delivering energy to production.

There are many end uses of compressed air energyapplied to all types of different industries. No two com-pressed air systems or compressed air system assess-ments are identical. Therefore, this Standard is providedas a flexible framework that, when applied to the widevariety of industrial compressed air systems,can accom-plish an effective energy and performance assessment.The system assessment framework is presented as a ma-trix of assessment objectives, action items, and methodolo-gies.The matrix approach is intended to facilitate selectionof activities to be performed in the assessment.Two matri-ces, “Preliminary Data Collection” and “Plan of Action,”are presented in Mandatory Appendices 1 and II. Eachmatrix includes required elements and supplemental ele-ments of assessment activity. Required elements primarilyfocus on energy reduction benefits and apply to virtuallyall compressed air systems. Supplemental elements de-scribed in each matrix do not apply to every system orhave primarily nonenergy related performance benefits.Ultimately, use of this Standard is at the discretion ofthose participating in the assessment. The assessmentteam (see para.4.1), working with production process in-formation and compressed air system knowledge, shallestablish the plan of action and statement of work (soW)for the assessment.

Plants that desire full conformance with this Standardshall complete all required elements of activity. Requiredelements, assessment objective, action item, and method-ology are shown in Mandatory Appendices I and ll usingblack text with white background. Each required ele-ment, assessment objective, and action item shall be in-vestigated using one or more methodologies also shownin black and white text.

ASME EA-4:2010 pdf free download