ASME B89.4.22:2004 pdf free download Methods for Performance Evaluation of Articulated Arm Coordinate Measuring Machines

1 sCOPE

The scope of this Standard pertains to the perform-ance evaluation of articulated arm coordinate measur-ing machines. While any number of rotational joints canbe evaluated, the Standard focuses on the more com-mon configurations commercially available today andis limited to seven joints.The Standard addresses purelymanual machines, so no motorized axes are addressedin the current document. While the application of thisclass of measuring machine continues to grow, at thispoint in time only contact probes are considered and op-tical noncontact probes are specifically excluded.

This Standard establishes requirements and methodsfor specifying and testing the performance of AACMMs.In addition to clarifying the performance evaluation ofAACMMs, this Standard seeks to facilitate performancecomparisons among machines by unifying terminology,general machine classification, the treatment of envi-ronmental effects, and data analysis.This Standard at-tempts to define the simplest testing methods capableof yielding adequate results for most AACMMs and itis not intended to replace more complete tests that maybe suitable for special applications.

This Standard provides definitions of terms applica-ble to AACMMs.These definitions are separated intotwo parts.The first part is a glossary covering technicalterms used throughout this and other ASME Standards.The second part defines a number of common machineclassifications.

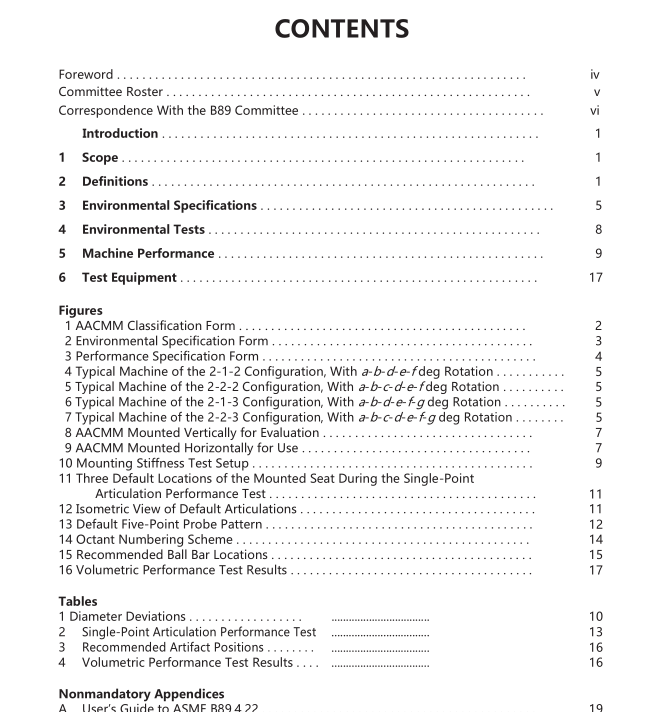

The actual specification is subdivided into threesections: general machine classification, machine envi-ronmental requirements, and machine performance.Machine classification includes machine type, measurement ranges, and rotary axis encoder resolution.Envi-ronmental specification includes thermal response, elec-trical requirements, and vibration sensitivity. Machineperformance specification includes effective diametertest, single-point articulation performance, and volu-metric performance tests.

Within this Standard, performance values are reportedas the maximum deviation, the range, and the standard

deviation.This is done to bring the Standard more into linewith existing national and international standards.

In order to clarify the use of this Standard, a shortguide on how to use it is included as Appendix A.

Productivity is an important consideration in the se-lection of an articulated arm coordinate measuring ma-chine.There are numerous factors that affect the rela-tive productivity of measuring systems, which includevariables attributable to both the measurement systemand the workpiece.This Standard does not addressmethods to specify and evaluate productivity. Produc-tivity should be evaluated with respect to the expecteduse of the system, including such aspects as software,ergonomics, and the frequency of calibration.

1.1 Contents and Specification Forms

Any specification described as complying with this Stan-dard shall include, as a minimum, the following items:(a) a machine classification form (see Fig. 1). If noclassification is applicable, the actual configuration shallbe described in equivalent detail.

(b)an environmental specification form (see Fig. 2).( a performance specification form (see Fig. 3).

1.2 Alternatives

This Standard allows parts of the environmental testsection to be deferred or bypassed and only the per-formance tests to be carried out.This alternative is ac-ceptable only if it is agreeable to both the user and thesupplier, and if deferred as specified.

2DEFINITIONS

2.1 Glossary

2.1.1 Terms.This glossary contains brief definitionsof the majority of technical terms used in this Standard.Some of the definitions listed are used in the nonmandatory appendices, but are included here for refer-ence purposes. Omissions and clarifications should bereported to ASME (see Correspondence).

ball bar: gage consisting of two highly spherical toolingballs of the same diameter connected by a rigid bar.Aball bar, as used in this Standard, must be sufficientlymechanically rigid that its length is constant during thecourse of aset of measurements.

bias (of a measuring instrument) systematic error of theindication of a measuring instrument.

NOTE: The bias of a measuring instrument is normally estimatedby averaging the error of indication over an appropriate numberof repeated measurements.

drift: slow change of a metrological characteristic of ameasuring instrument.

ASME B89.4.22:2004 pdf free download