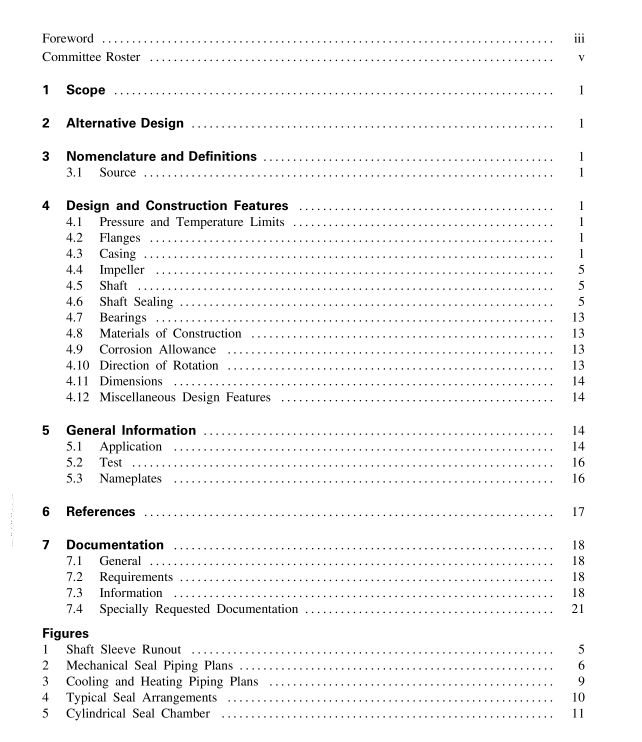

ASME B73.1:2001 pdf free download SPECIFICATION FOR HORIZONTAL END SUCTION CENTRIFUGAL PUMPS FOR CHEMICAL PROCESS

1 SCOPE

This Standard covers centrifugal pumps of horizontal, end suction single stage, centerline discharge design. This Standard includes dimensional interchangeability requirements and certain design features to facilitate installation and maintenance. It is the intent of this Standard that pumps of the same standard dimension designation from all sources of supply shall be inter- changeable with respect to mounting dimensions, size and location of suction and discharge nozzles, input shafts, baseplates, and foundation bolt holes (see Tables 1 and 2). 2 ALTERNATIVE DESIGN Alternate designs will be considered, provided they meet the intent of this Standard and cover construction and performance which are equivalent to and otherwise in accordance with these specifications. All deviations from these specifications shall be described in detail.

3 NOMENCLATURE AND DEFINITIONS

3.1 Source All nomenclature and definitions of pump components shall be in accordance with HI 1.1–1.2.

4 DESIGN AND CONSTRUCTION FEATURES

4.1 Pressure and Temperature Limits

4.1.1 Pressure Limits. Pressure limitations shall be stated by the pump manufacturer.

4.1.1.1 The design pressure ofthe casing, including stuffing box or seal chamber and gland, shall be at least as great as the pressure-temperature rating of ASME B16.5 or ASME B16.42 Class 150 flanges for the material used.

4.1.1.2 The design pressure of jackets shall be at least 100 psig (690 kPa gage) at 340°F (170°C). Heating jackets may be required for jacket temperatures to 500°F (260°C) with a reduction in pressure corres- ponding to the reduction in yield strength of the jacket material.

4.1.1.3 Casing, stuffing box, cover or seal chamber, and jackets shall be designed to withstand a hydrostatic test at 1.5 times the maximum design pressure for the particular component and material of construction used (see para. 5.2.1).

4.1.2 Temperature Limits. Temperature limita- tions shall be stated by the pump manufacturer. Pumps should be available for temperatures up to 500°F (260°C). Jacketing and other modifications may be required to meet the operating temperature.

4.2 Flanges Suction and discharge nozzles shall be flanged. Flanges shall conform to ASME B16.5 or ASME B16.42 Class 150 standards except that marking requirements are not applicable and the maximum acceptable tolerance on parallelism of the back of the flange shall be 3 deg and bolt holes may be tapped where noted in Table 1. Through bolt holes are preferred. When tapped holes are supplied, they shall be noted on the outline drawing. As an option, Class 300 flanges in accordance with ASME B16.5 or ASME B16.42 may be offered subject to the manufacturer’s casing pressure-temperature limitations. All pumps regardless of flange rating shall conform to the X and Y dimensions shown in Table 1.

4.3 Casing

4.3.1 Drain Connection Boss(es). Pump casing shall have boss(es) to provide for drain connection(s) in the lowest part of the casing. Boss size shall accom- modate 1 ⁄ 2 in. NPT min. Boss(es) shall be drilled and tapped when specified by customer.

4.3.2 Auxiliary Connection Boss(es). The suc- tion and discharge nozzles shall have boss(es) for gage connections. Boss size shall accommodate 1 ⁄ 4 in. NPT min., 1 ⁄ 2 in. NPT preferred. Boss(es) shall be drilled and tapped when specified by customer.

4.3.3 Support. The casing shall be supported by feet beneath the casing or a suitable support between the casing and baseplate.

4.3.4 Disassembly. The design shall permit back removal of the rotating element from the casing without disturbing the suction and discharge connections or the driver. Tapped holes for jackscrews, orequivalent means, shall be provided to facilitate disassembly of the casing and stuffing box cover or seal chamber and to avoid the necessity of drive wedges or prying implements.

4.3.5 Jackets

4.3.5.1 Jackets for heating or cooling the casing, stuffing box, or seal chamber are optional. Connection shall be 3 ⁄ 8 in. NPT min., with 1 ⁄ 2 in. NPT preferred. When a jacket is to be used for heating by steam, the inlet connection shall be located at the top quadrant of the casing, stuffing box, or seal chamber; and the drain connection shall be located at the bottom portion of the casing, stuffing box, or seal chamber to prevent the formation of water pockets. Jackets for water cooling shall have a drain for freeze protection.

ASME B73.1:2001 pdf free download