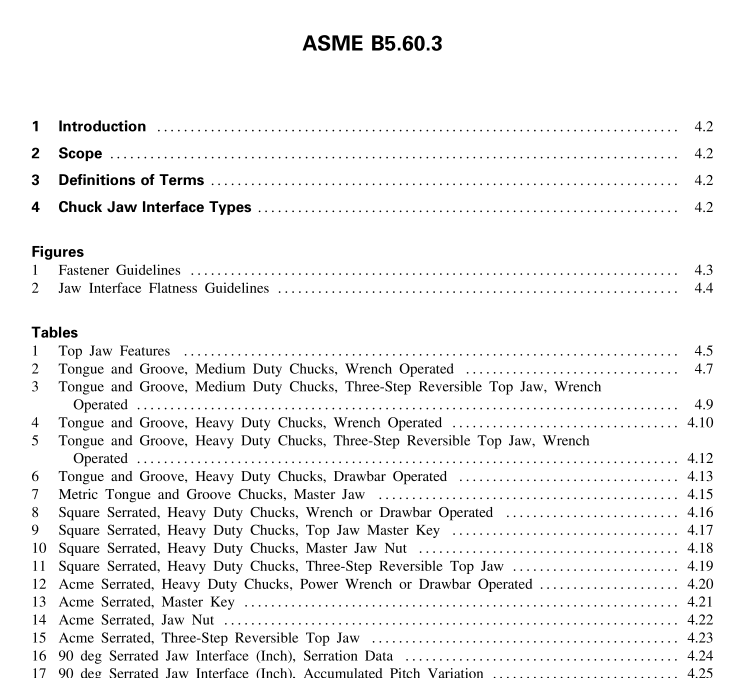

ASME B5.60B:2009 pdf free download JAW MOUNTINGS

1 INTRODUCTION

This American National Standard establishes techni-cal requirements for workholding chucks used primarilyin turning operations.It covers jaw type chucks whethermanual or power operated.

2 scOPE

This Part of the ASME B5.60 Standard covers theinterface of two-piece chuck jaws.

3 DEFINITIONS OF TERMS

fasteners:accessory devices (usually threaded) thatare used to secure the top jaw onto the master jaw(see Fig. 1).

groove (slot):a recessed geometric form that receivesa tongue,key,or jaw nut for positioning the top jawwith the master jaw.

hard top jaw:a top jaw that is made to its final sizeof hardenable steel. It is not intended to be machinedin use.

jaw interface:geometric forms with fastening ele-ments that position and secure top jaws to master jaws(see Fig. 2).

jaw nut:the fastener used in the master jaw forsecuring and, in some designs, positioning the top jawwith the master jaw.

jaw-nui slot:a T-slot in the master jaw for receivinga jaw nut.

master jaw (base jaw):radial-moving part within thechuck body to which the top jaw is mounted.

master jaw pins:precision pins that position the topjaw with the master jaw.

master key: a serrated positioning key, secured in thetop jaw.

monoblock (solid style jaw): a one-piece combinationmaster and top jaw.

serration: a repetitive geometric form for radial posi-tioning the top jaw with the master jaw.

soft top jaw (blank jaw): a top jaw that is not heat-treated and is formed prior to usage.

tongue:the projected geometric form that aligns thetop jaw with the master jaw.

top jaw: component that clamps the workpiece andis mounted on a master jaw.

4 CHuCK JAW INTERFACE TYPES

See Table 1 for top jaw features.

ASME B5.60B:2009 pdf free download