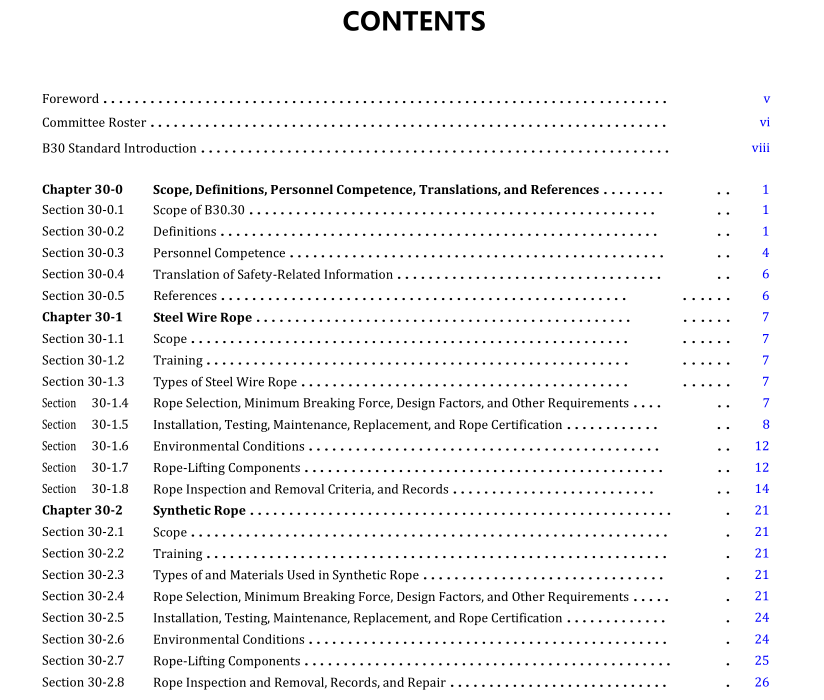

ASME B30.30:2019 pdf free download Ropes Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings

SECTION 30-0.1: SCOPE OF ASME B30.30Volume B30.30 includes provisions that apply to theconstruction,selection, installation, attachment, testing,inspection, maintenance, repair, use, and replacementof wire rope, hybrid rope, and synthetic fiber rope andrope-lifting components used in conjunction with equip-ment addressed in the volumes of the ASME B30 Standard.These provisions apply to a particular volume when

B30.30 is referenced and as specified in that volume.

SECTION 30-0.2: DEFINITIONS

aramid fiber: a manufactured, high modulus fiber madefrom a long-chain synthetic aromatic polyamide in which at least 85% of the amide linkages join two aromaticrings.

birdcage: a rope condition that results in deformation withthe outer strands being displaced away from the rope axis.lt is usually the result of shock loading or localized twistingin a rope (see Figure 30-0.2-1).

braid: a rope or textile structure formed by intertwiningstrands.

double braid: a rope constructed from an inner hollowbraided rope (core) surrounded by another hollow braided rope (cover) (also known as braid-on-braid ortwo-in-one braid).

single braid: rope structure consisting of multiple

strands that may be intertwined in a plain or twill pattern.crown break: a wire break located on the outside of therope that occurs above the strand-to-strand contact pointswith both ends visible (see Figure 30-0.2-2].

D/d ratio: the ratio of the pitch diameter of the sheaveor drum, D, to the nominal rope diameter, d (see Figure30-0.2-3).

denier: a mass-per-unit-length measure equal to theweight in grams of 9 000 m of the material. Denier is adirect numbering system in which the lower numbersrepresent the finer sizes and the higher numbers thecoarser sizes.

design factor: the minimum breaking force of the rope in arope system divided by the maximum static tension in therope.

dogleg, minor: a bend or deformation exhibiting no asso-ciated strand distortion and that cannot be observed whilethe rope is under tension.

dogleg, severe: a permanent, localized, irreparable bend ordeformation in a wire rope that restricts the natural

adjustment of the rope’s components during operationdue to strand distortion.It is caused by improper useor handling and results in an indeterminate loss ofstrength in the rope (see Figure 30-0.2-4).

fiber core: a wire rope center component consisting ofman-made or natural (vegetable) materials whosepurpose is to support the outer strands of the wire

rope and is not included as one of the load-bearing compo-nents of the wire rope when calculating the minimum

breaking force.

fleet angle: the angle between the rope’s position on adrum or sheave and the line drawn perpendicular tothe axis of the drum or sheave through the center ofthe nearest fixed sheave (see Figure 30-0.2-5).

groove corrugation: a repetitive pattern in the groove of asheave or drum caused by wear at the contact point witheach rope strand that may cause rope wear and distortion.guy: a fixed length of strand or rope for stabilizing or main-taining a structure in a fixed position or a constant

distance between the two components connected bythe rope.

heavy rope service: service that involves operating at 85%to 100% of rope rated load or in excess of ten lift cycles perhour as a regular specified procedure.

high modulus polyethylene (HMPE): a polyolefin fiberproduced by gel spinning or solid-state extrusion of anultra-high-molecular-weight polyethylene (UHMWPE)feedstock to produce extremely high tenacity [alsoknown as extended-chain polyethylene (ECPE) or high-performance polyethylene (HPPE)].

hours of rope operation: the actual or estimated operatingtime of the rope.

hybrid rope: a wire rope consisting of both synthetic andsteel components. The synthetic components are includedas load-bearing components of the rope when calculatingits minimum breaking force.

independent wire rope core (IWRC): a wire rope used as the axial member of a larger wire rope.

kink: a deformation in a wire rope caused by a loop of rope being pulled tight. It represents irreparable damage and an indeterminate loss of strength in the rope.

ASME B30.30:2019 pdf free download