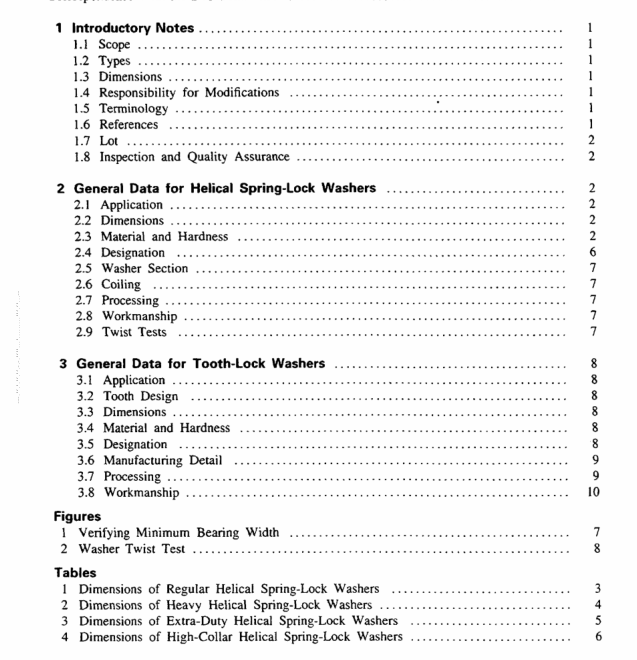

ASME B18.21.1:1999 pdf free download LOCKWASHERS (INCH SERIES)

2.7 Processing

2.7.1 Finishes. Unless otherwise specified by the purchaser, lock washers shall be supplied with a plain (as processed) finish, not plated or coated. Where corrosion preventative treatment is required, washers shall be plated or coated as specified by the purchaser. When helical spring-lock washers are to be fumished with coatings over 0.0005 in. thick and are to be used with bolts or screws also having thicker coatings, they are to be coiled to limits of 0.020 in. in excess of those specified in Tables 1 through 4 for minimum inside diameter and maximum outside diameter. Heavy coating of washers under /4 in. nominal size is not recommended.

2.7.2 Embrittlement. Carbon and boron steel-lock washers that are electroplated or coated may be subject to embittlement and shall be suitably treated to mini- mize such embrittlement. Plated washers shall not frac- ture after having been compressed flat for a minimum of48hr.

2.8 Workmanship The fat sufaces (faces) of helical spring-lock washers shall be free from such surface imperfections as knurling, serrations, die marks, deep scratches, loose scale, burrs, or other irregularities that would affect serviceability. Moderate feed roll marks shall be permissible on the outer periphery.

2.9 Twist Tests The washer shall be gripped in vise jaws. The ends of the washer shall be free, and an axis passing through the slot shall be parallel to and slightly above the top of the vise so less than 50% of the washer is gripped. A 90 deg maximum segment of the free end of the washer shall be gripped in wrench jaws so at least25% of the washer is exposed when twisting, as shownin Fig. 2.Edges of the wrench jaws shail be in aplane parallel to the vise. Movement of the wrenchthat increases the free height of the spring-lock washershall twist carbon steel,boron steel,and alloy steelwashers through an angle approximating 90 deg, andcorrosion resistant steel and nonferrous washers throughan angle approximating 45 deg with no sign of fracture.

3GENERAL DATA FOR TOOTH-LOCK wASHERS

3.1 Application

The tooth-lock washers covered in this Standard areintended for general application. The tooth-lock washersserve to increase the friction between the screw andthe assembly. Intemal tooth-lock washers are preferredwhere it is desirable to provide a smooth periphery.

3.2 Tooth Design

The Type A and Type B tooth designs shall beoptional.

3.3 Dimensions

Dimensions of internal tooth-lock washers,heavyinternal tooth-lock washers, external tooth-lock washers,and internal/external tooth lock washers shall be asspecified in Tables 6 through 10.

3.4 Material and Hardness

3.4.1 Material Composition. Washers shall bemade from material meeting the chemical compositionrequirements of one of the following standards:

washer shall be gripped in wrench jaws so at least25% of the washer is exposed when twisting, as shownin Fig. 2.Edges of the wrench jaws shail be in aplane parallel to the vise. Movement of the wrenchthat increases the free height of the spring-lock washershall twist carbon steel,boron steel,and alloy steelwashers through an angle approximating 90 deg, andcorrosion resistant steel and nonferrous washers throughan angle approximating 45 deg with no sign of fracture.

3GENERAL DATA FOR TOOTH-LOCK

wASHERS

3.1 Application

The tooth-lock washers covered in this Standard areintended for general application. The tooth-lock washersserve to increase the friction between the screw andthe assembly. Intemal tooth-lock washers are preferredwhere it is desirable to provide a smooth periphery.

3.2 Tooth Design

The Type A and Type B tooth designs shall beoptional.

3.3 Dimensions

Dimensions of internal tooth-lock washers,heavyinternal tooth-lock washers, external tooth-lock washers,and internal/external tooth lock washers shall be asspecified in Tables 6 through 10.

3.4 Material and Hardness

3.4.1 Material Composition. Washers shall bemade from material meeting the chemical compositionrequirements of one of the following standards:

(a) Carbon Steel.SAE J403 1050-1065 or equivalent(UNS G10500-G10650).

(b) Stainless Steel. SAE J405 301-305 (UNSs30100-S30500) or SAE J405 316 (UNs s31600).(c)Stainless Steel.SAE J405 410 (UNs S41000).

(d)Copper Alloy. ASTM B 591Type 425 (UNSc42500).

Other materials and grades shall be as agreed uponby the manufacturer and purchaser.

3.4.2 Hardness. Washers that are manufacturedfrom carbon steel that show evidence of decarburization,or parts that were plated, shall have these surface layersremoved before checking. During this operation,careshall be exercised to prevent the surface temperatureof the washer from exceeding 250°F. It is recommendedthat the lighter,more sensitive depth reading HRAscale be used in lieu of HRC when testing washersof a thin section. Hardness requirements applicable towashers of the respective materials shall be as follows.Refer to ASTM E 140 for hardness conversions.(a)Carbon Steel. 40 to 50 HRC,392 to 513 HV.

(b)Stainless Steel 301-305.Annealed 88 minimum.HRB,%4 hard through full hard 20 to 45 HRC,198to 448 HV.

(c)Stainless Steel 410.40 to 50 HRC, 392 to 513 HV.(d)Copper Alloy.Temper HO6 minimum.

ASME B18.21.1:1999 pdf free download