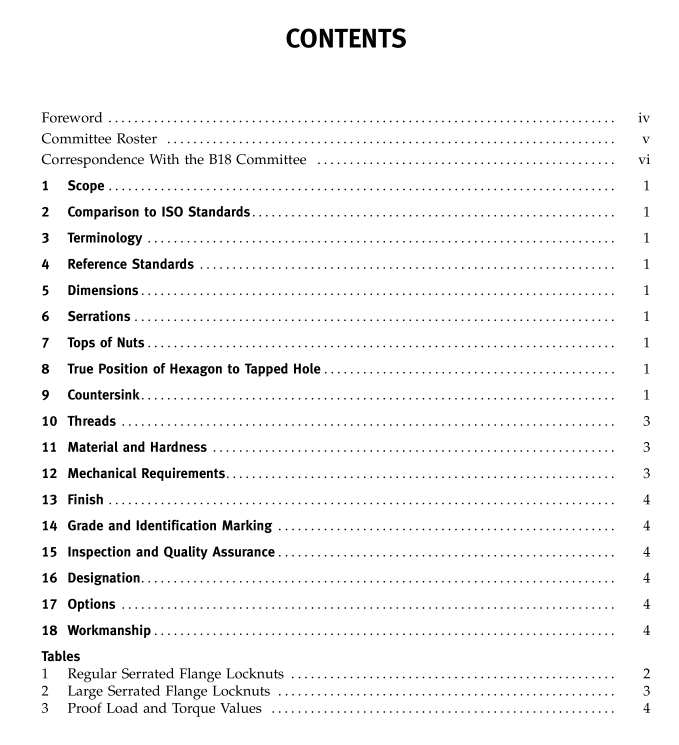

ASME B18-16.4:2008 pdf free download Serrated Hex Flange Locknuts 90,000 psi (Inch Series)

1 sCOPE

This Standard covers the general,dimensional,andmechanical performance requirements for low strengthcarbon steel, case hardened, regular and large serratedflange locknuts (inch series),recognized as AmericanNational Standard.

2 COMPARISON To lso STANDARDS

There is no inch series ISO standard for these productsat this time.

3TERMINOLOGY

For definitions of terms relating to fasteners orcomponent features used in this Standard, refer toASME B18.12.

REFERENCE STANDARDS

The following is a list of publications referenced inthis Standard.

ASME B1.1,Unified Inch Screw Threads

ASME B1.3,Screw and Thread Gaging Systems forDimensional Acceptability — Inch and Metric ScrewThreads (UN,UNR, UNJ, M, and MJ)

ASME B18.12,Glossary of Terms for MechanicalFasteners

ASME B18.18.2M, Inspection and Quality Assurance forHigh-Volume Machine Assembly Fasteners

ASME Y14.5M,Dimensioning and Tolerancing

Publisher: The American Society Of MechanicalEngineers (ASME),Three Park Avenue,New York,NY 10016-5990; Order Department: 22 Law Drive,P.O.Box 2300,Fairfield, NJ 07007-2300

ASTM F 606,Test Methods for Determining theMechanical Properties of Externally and InternallyThreaded Fasteners,Washers,Direct TensionIndicators, and Rivets

ASTM F 812,Specification for Surface Discontinuitiesof Nuts,Inch Series

ASTM F 1941,Electrodeposited Coatings on ThreadedFasteners [Unified Inch Screw Threads (UN/UNR)]ASTM F 2282,Standard Specification for QualityAssurance Requirements for Carbon and Alloy SteelWire,Rods, and Bars for Mechanical Fasteners

ASTM F 2328,Standard Test Method for DeterminingDecarburization and Carburization in Hardened andTempered Threaded Steel Bolts, Screws, and StudsPublisher: ASTM International,100 Barr Harbor Drive,P.O. Box C700,West Conshohocken, PA 19428-2959

5 DIMENSIONS

(a)Unless otherwise specified, all dimensions in thisStandard shall be as specified in Tables 1 and 2, andsections 6 through 9.All dimensions in this Standardare in inches and apply before plating or coating isspecified. When a plating or coating is specified, thefinished product dimensions shall be agreed uponbetween the supplier and purchaser.

b) Symbols specifying geometric characteristics arein accordance with ASME Y14.5M.

6SERRATIONS

The configuration of the serrations shall be at thediscretion of the manufacturer, provided the perform-ance requirements as specified in para.12.2 are met.

7 Tops OF NUTS

Tops of nuts shall be flat and chamfered.The lengthof chamfer at hex corners shall be from 5%to 15%ofthe basic thread size. The surface may be slightly convexor rounded.

8TRUE POSITION OF HEXAGON TO TAPPED HOLEAt maximum material condition(MMC),the axis ofthe hexagon shall be located at true position with respectto the axis of the thread pitch diameter within a tolerancezone having a diameter equivalent to 4% of the maxi-mum width across flats.

cOUNTERSINK

Tapped hole shall be countersunk on the bearing faceand may be countersunk on the top. The maximumcountersink diameter shall be the thread basic (nominal)major diameter plus 0.030 in. for 3’/g in. nominal size nutsand smaller, and 1.08 times the basic major diameter for nuts larger than 3 ⁄ 8 in. No part of the threaded portion shall project beyond the bearing surface.

10 THREADS Threads shall be Unified coarse or fine thread series (UNC or UNF series) Class 2B, in accordance with ASME B1.1. Inspection shall be based on System 21 of ASME B1.3.

11 MATERIAL AND HARDNESS Unless otherwise specified, nuts shall be manufac- turedfromcarbonsteelinaccordance withASTMF2282. The nuts shall have a case hardness of HR 15N 78-90 on the surface of the nut in accordance with ASTM F 2328. For referee purposes, case hardness shall be measured in the serrations.

12 MECHANICAL REQUIREMENTS

12.1 Proof Load Test Nuts shall meet the proof load test using the values in Table 3. The proof load test procedure from ASTM F 606 shall be followed.

12.2 Break Loose Torque Test Nuts shall have a break loose torque value equal to or greater than 100% of the seating torque value. The seating torque value shall be ±10% of the values listed in Table 3.

ASME B18-16.4:2008 pdf free download