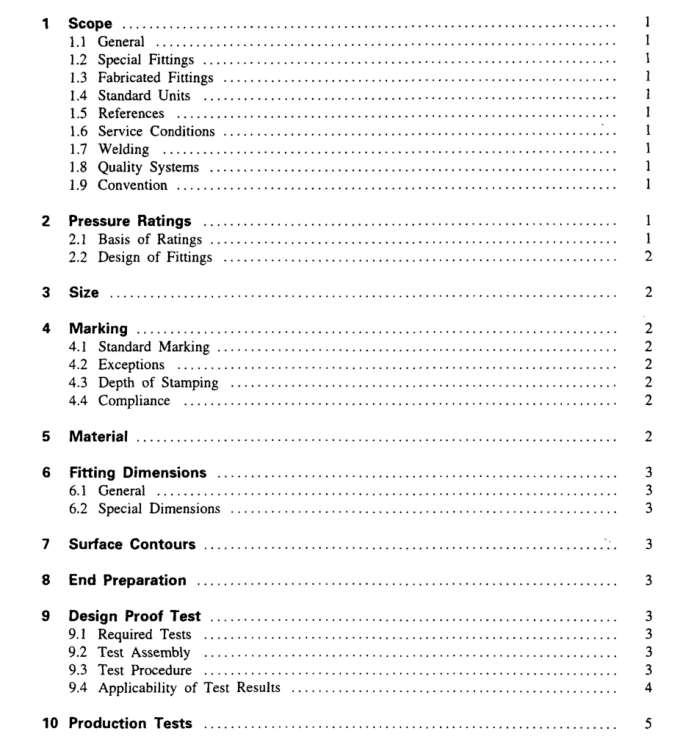

ASME B16.9:2001 pdf free download FACTORY-PA ADE WROUGHT BUTTWELDINC FITTINGS

1 SCOPE

1.1 General This Standard covers overall dimensions, tolerances, ratings, testing, and markings for wrought factory-made buttwelding fittings in sizes NPS ‘/2 through 48 (DN 15 through 1200).

1.2 Special Fittings Fittings may be made to special dimensions, sizes, shapes, and tolerances by agreement between the manufacturer and the purchaser.

1.3 Fabricated Fittings Fabricated laterals and other fittings employing circumferential or intersection welds are considered pipe fabrication, and are not within the scope of this Standard.

1.4 Standard Units The values stated in either metric or U.S. Customary units are to be regarded separately as standard. Within the text, the U.S. Customary units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this Standard. The designations for pressure rating and size are Class and NPS for both metric and customary dimen- sioned fittings. The designations PN and DN used in international standards are shown for reference conve- nience.

1.5 References

1.5.1 Referenced Standards. Standards and spec- ifications adopted by reference in this Standard are shown in Mandatory Appendix II. It is not considered practical to identify the specific edition of each standard and specification in the individual references. Instead, the specific edition reference is identified in Mandatory Appendix II. A product made in conformance with a prior edition of reference standards and in all other respects conforming to this Standard will be considered to be in conformance.

1.5.2 Codes and Regulations. A fitting used under the jurisdiction of the ASME Boiler and Pressure Vessel Code, the ASME Code for Pressure Piping, or a governmental regulation is subject to any limitation of that code or regulation. This includes any maximum temperature limitation, or rule governing the use of a material at low temperature.

1.6 Service Conditions Criteria for selection of fitting types and materials suitable for particular fluid service are not within the scope of this Standard.

1.7 Welding Installation welding requirements are outside the scope of this Standard.

1.8 Quality Systems Nonmandatory requirements relating to the fitting manufacturer’s Quality System Program are described in Nonmandatory Appendix A.

1.9 Convention For the purpose of determining conformance with this Standard, the convention for fixing significant digits where limits, maximum or minimum values, are speci- fied shall be rounded off as defined in ASTM E 29. This requires that an observed or calculated value shall be “rounded off’ to the nearest unit in the last right- hand digit used in expressing the limit. Decimal value in the last and tolerances do not imply a particular method of measurement.

2 PRESSURE RATINGS

2.1 Basis of Ratings The allowable pressure ratings for fittings designed in accordance with this Standard may be calculated as for straight seamless pipe of equivalent material (as shown by comparison of composition and mechanical properties in the respective materiai specifications) in accordance with the rules established in the applicable sections of ASME B31, Code for Pressure Piping. For the calculation, applicable data for the pipe size, wall thickness, and material that is equivalent to that of the fitting shall be used. Pipe size, wall thickness (or schedule number), and material identity on the fittings are in lieu of pressure rating markings.

2.2 Design of Fittings The design of fittings shall be established by mathe- matical analyses (e.g. ASME B16.49 for bends) con- tained in nationally recognized pressure vessel or piping codes or at the manufacturer’s option by proof testing in accordance with section 9 of this Standard. In order to meet design or manufacturing requirements, it is expected that some portion of formed fittings may have to be thicker than the pipe wall with which the fittings is intended to be used. The mathematical analyses, if used, may take into account such thicker sections. Records of mathematical analysis and/or successful proof test data shall be available at the manufacturer’s facility for inspection by the purchaser.

ASME B16.9:2001 pdf free download