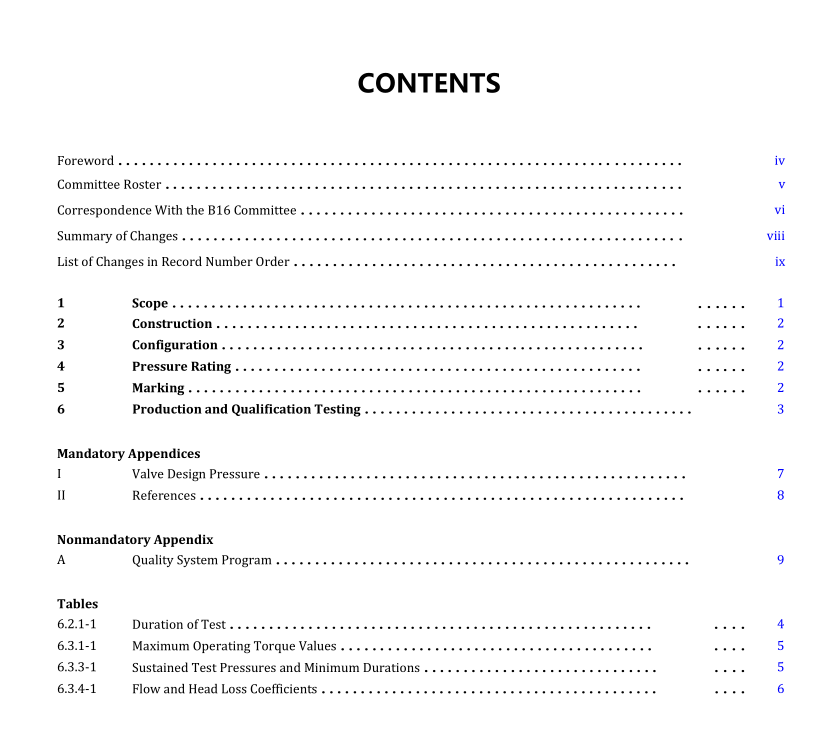

ASME B16.40:2019 pdf free download Manually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution Systems

6 PRODUCTION AND QUALIFICATION TESTING

6.1 General

(a) Gas tightness of production valves shall be demon- strated by subjecting each valve to shell and seat tests in accordance with para. 6.2.

(b) Each basic valve design shall be qualified by testing randomly selected production valves in accordance with para. 6.3.

(c) Leak test fluid shall be air or other gas. During leakage testing, there shall be no visible leakage (breaking away or buildup of bubbles) as measured by the immer- sion or leak detection solution methods.

If immersion is used, the depth from the water surface shall be no more than 12 in. (300 mm). Other means of leak detection may be used, provided they are equivalent in leak detection sensitivity.

6.2 Production Testing

6.2.1 Shell Test. Each valve shall be tested at 4 psi ± 2 psi (0.28 bar ± 0.14 bar) and at a minimum of 1.5 times the design pressure. The test pressure shall be applied to all pressure-containing areas of the valve (including stem seals and valve ends). This may require the valve to be in the partially open position. The shell test shall be conducted at a temperature of 73°F ± 15°F (23°C ± 8°C). The test fixturing shall not restrain the valve against any mode of failure or leakage. The minimum duration of each of the two shell tests shall be as shown in Table 6.2.1-1.

6.2.2 Seat Test. Each valve shall be seat closure tested at 4 psi ± 2 psi (0.28 bar ± 0.14 bar) and at a minimum of 1.5 times the valve design pressure. These pressures shall be applied successively on each side of the valve seat(s) to check the valve-sealing performance in both directions. The seat test shall be conducted at a temperature of 73°F ± 15°F (23°C ± 8°C). The seat test’s fixturing shall not restrain the valve against any mode of failure or leakage. The minimum duration of each portion of the test shall be as shown in Table 6.2.1-1.

6.3 Qualification Testing

6.3.1 Operational Test. It shall be demonstrated that each nominal size of each basic valve design is capable of successfully passing the seat leakage tests of para.

6.2.2 after having completed ten fully opened/closed cycles at 73°F ± 15°F (23°C ± 8°C). The valve shall be pressurized with air or other gas to the design pressure at one port with the other port open to atmosphere before opening on each cycle. At the start of each cycle, the operating torque shall be measured and not exceed those in Table 6.3.1-1 for −20°F (−29°C).

6.3.2 Temperature Resistance.

It shall be demon- strated that each nominal size of each basic valve design is capable of being operated at temperatures of −20°F ± 5°F (−29°C ± 3°C) and 140°F ± 5°F (60°C ± 3°C) without visible leakage to atmosphere and without affecting the internal seat-sealing performance of the valve.

The test method is as follows:

a closed valve shall be cooled to a temperature of −20°F ± 5°F (−29°C ± 3°C) and held at that temperature for a minimum of 18 hr. The valve shall then be pressurized with air or gas to a differential pressure across the seat equal to the valve design pressure. The valve shall then be opened against the applied-differential pressure, using a torque less than or equal to that of Table 6.3.1-1 at the −20°F (−29°C) values and then closed (no differential pressure across the seat required). The valve shall then be tested to meet the requirements of para.

6.2 while at −20°F (−29°C), except nonfreezing leak-detection agents shall be used. The valve shall be heated to a temperature of 140°F ± 5°F (60°C ± 3°C) and held at that temperature for a minimum of 18 hr.

The closed valve shall then be pressurized with air or other gas to a differential pressure across the seat equal to the valve’s design pressure at 140°F (60°C). The valve shall then be opened against the applied-differ- ential pressure using a torque less than or equal to that of Table 6.3.1-1 values [140°F (60°C)] and then closed (no differential pressure across the seat required). The valve shall then be tested to and meet the requirements of para. 6.2 while at 140°F (60°C). 6.3.3 Sustained-Pressure Test.

Each basic valve 1 9 design shall be subjected to the sustained-pressure tests described herein to evaluate the long-term pressure integrity of the valve shell and closure elements. All valves shall be in the open position for the pressure-boundary test [see (a)] and in the closed position for the valve closure test [see (b)]. For both PE and PA-11, Table 6.3.3-1 offers two choices of pressures and duration times for the sustained pressure test. The valve manufacturer shall test for 1,000 hr at the lower listed pressures, depending on valve DR, or for 170 hr at the higher listed pressures. Either choice is valid. The valve manufacturer is not required to perform both tests. For NVS < 1 1 ∕ 4 , the sustained-pressure tests may use Table 6.3.3-1 DR 9.3 pressure values. The valves shall not fail, as defined in ASTM D1598, when subjected to the sustained pressure test.

ASME B16.40:2019 pdf free download