ASME B16.3:2011 pdf free download Malleable Iron Threaded Fittings Classes 150 and 300

(a) Metal Thickness Tolerances. Metal thickness at no point in the castings shall be less than 90% of the value given in the tables.

(b) Center-to-End Tolerances. Permitted tolerances on the center-to-end dimensions of the fittings are shown inTables 2 and I-2. Tolerances for end-to-end dimensions and lengths of couplings and reducers shall be twice those given. The largest opening in a reducing fitting governs the tolerances to be applied to all openings. These tolerances do not apply to return bends and caps.

8 THREADING

8.1 Types of Threads All fittings shall be threaded according to ANSI/ASME B1.20.1, and shall have taper threads, except wrought couplings (Tables 8 and I-8) and wrought caps (Tables 9 and I-9) in NPS 1 ⁄ 8 , 1 ⁄ 4 , and 3 ⁄ 8 , which may have straight threads.

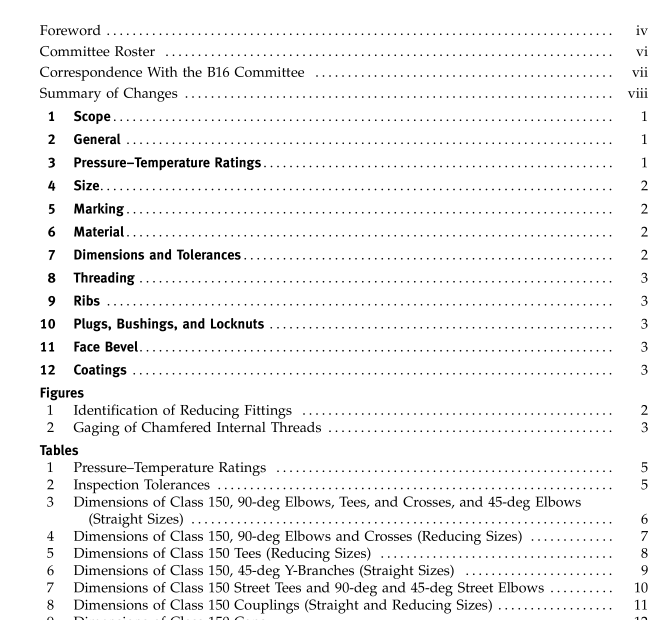

8.2 Tolerances Variations in taper threading shall be limited to one turn large or one turn small from the gaging face on ring and gaging notch on plug when using working gages. The variations in straight threading shall be lim- ited to one and one-half turns large or small from the gaging notch on plug when using a taper pipe thread working gage. The reference point for gaging internal fittings threads depends upon the chamfer diameter. When the internal chamfer diameter exceeds the major diameter of the internal thread, the reference point is the last thread scratch on the chamfer cone. When the internal chamfer diameter does not exceed the major diameter of the internal thread, the reference point is the end of the fitting (see Fig. 2). 8.3 Countersink or Chamfer For the purpose of easier entrance in making a joint and for protection ofthe thread, all internal threads shall be countersunk a distance of not less than one-half the pitch of the thread at an angle of approximately 45 deg with the axis of the thread; all external threads shall be chamfered at an angle of 30 deg to 45 deg with the axis. Countersinking and chamfering shall be concentric with the threads.

8.4 Thread Length The length of threads specified in all tables shall be measured to include the countersink or chamfer.

8.5 Alignment The maximum allowable variation in the alignment of threads of all openings of threaded fittings shall be 5.0 mm/m (0.06 in./ft) (0.5% slope).

9 RIBS

9.1 General The addition of ribs or lugs is permitted on threaded fittings. Where ribs are used, it is recommended that their thickness be the same as specified for metal thick- ness of the fitting. Right-hand couplings shall have not more than two ribs.

9.2 Special Couplings Rightand left-hand couplings shall have four or more ribs unless the left-hand opening is clearly marked, in which case the use of ribs is optional with the manufacturer.

10 PLUGS, BUSHINGS, AND LOCKNUTS For dimensions of plugs, bushings, and locknuts to beusedinconnectionwithClasses150 and 300 malleable iron threaded fittings, see ASME B16.14.

11 FACE BEVEL A bevel not exceeding 5 deg is permitted on the faces of fitting openings. Center-to-end, end-to-end, and width of band dimensions may include or exclude the bevel. 12 COATINGS

12.1 Malleable Iron Fittings When malleable iron fittings are zinc coated, they shall be hot dipped in accordance with ASTM A153 or

ASME B16.3:2011 pdf free download