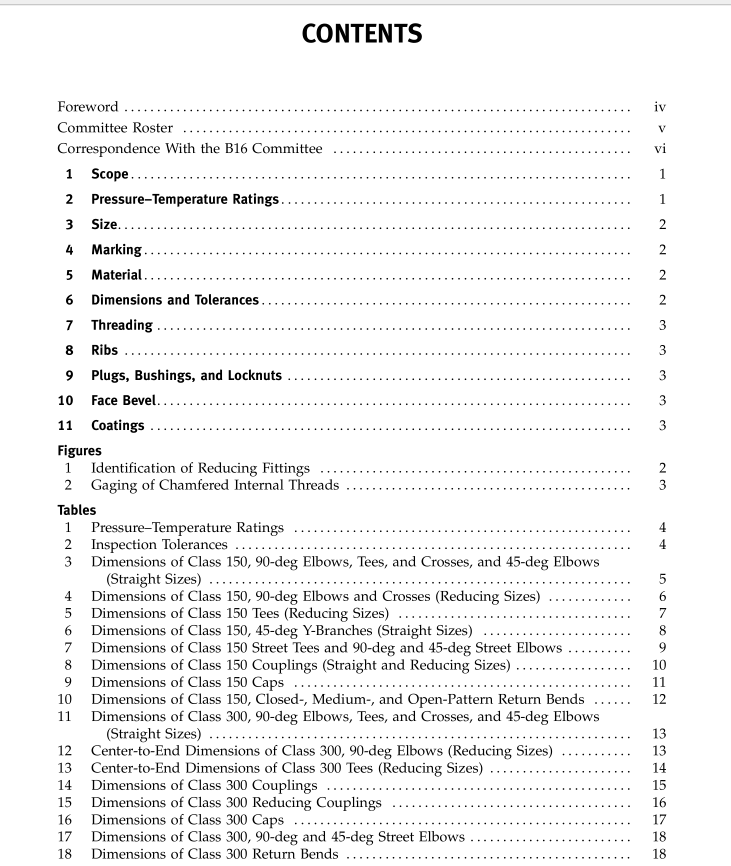

ASME B16.3:2006 pdf free download Malleable Iron Threaded Fittings Classes 150 and 300

1 sCOPE1.1 General

This Standard covers malleable iron threaded fittings,Classes 150 and 300.It also contains provisions for usingsteel for caps and couplings in Class 150 for NPS / andsmaller. This Standard includes

(a) pressure-temperature ratings

(b) size and method of designating openings of reduc-ing fittings

(c) marking(d) material

(e) dimensions and tolerances

(f) threading

ig) coatings

Mandatory Appendix I provides table values in U.S.Customary units.

1.2 References

Standards and specifications adopted by reference inthis Standard are shown in Mandatory Appendix II. Itis not considered practical to identify the specific editionof each referenced standard and specification in the text.Instead, the specific editions of the referenced standardsand specifications are listed in Mandatory Appendix II.1.3 Quality Systems

Requirements relating to the product manufacturers’Quality System Programs are described in Nonmanda-tory Appendix A.

1.4Relevant Units

This Standard states values in both metric and U.s.Customary units. These systems of units are to beregarded separately. Within the text, the U.S.Customaryunits are shown in parentheses or in separate tables.The values stated in each table are not exact equivalents;therefore, it is required that each system of units be used

independently of the other.ombinine vauesfeu steatwo systems constitutes nonconformance with this

Standard.

1.5 Service Conditions

Criteria for selection of materials suitable for particu-lar fluid service are not within the scope of this Standard.

1.6 Convention For the purpose of determining conformance with this Standard, the convention for fixing significant digits where limits (maximumand minimumvalues) are speci- fied, shall be rounded as defined in ASTM E 29. This requires that an observed or calculated value shall be rounded off to the nearest unit in the last right hand digit used for expressing the limit. Decimal values and tolerance do not imply a particular method of mea- surement.

1.7 Denotation

1.7.1 Pressure Rating Designation. Class, followed by a dimensionless number, is the designation for pres- sure–temperature ratings as follows: Class 150; Class 300.

1.7.2 Size. NPS, followed by a dimensionless num- ber, is the designation for nominal fitting size. NPS is related to the referenced nominal diameter, DN, used in international standards. The relationship is, typically, as follows:

GENERALNOTE: For NPS ≥4, the related DN is: DN p 25 ? (NPS).

2 PRESSURE–TEMPERATURE RATINGS

(a) Pressure–temperature ratings for these fittings are shown in Tables 1 and I-1.

(b) All ratings are independent of the contained fluid and are the maximum allowable working gauge pres- sures at the tabulated temperatures. Intermediate ratings may be obtained by linear interpolation between the temperatures shown.

(c) The temperatures shown for the corresponding pressure rating shall be the material temperature of the pressure-retaining structure. It may be assumed that the material temperature is the same as the fluid tempera- ture. Use of a pressure rating at a material temperature other than thatofthe contained fluid is the responsibility of the user and subject to the requirements of any appli- cable code.

(d) Class 300 street elbows are not recommended for pressures above 600 psi.

3 SIZE

3.1 Nominal Pipe Size As applied in this Standard, the use of the phrase “nominal pipe size” or the designation NPS followed by a dimensionless number is for the purpose ofidentifying the end connection of fittings. The number is not neces- sarily the same as the fitting inside diameter.

3.2 Reducing Fittings For reducing tees, crosses, and Y-branches (laterals), the size of the largest run opening shall be given first, followed by the size of the opening at the opposite end of the run. Where the fitting is a tee or Y-branch (lateral), the size of the outlet is given last. Where the fitting is a cross, the largest side-outlet opening is the third dimension given, followed by the opposite opening. The straight-line sketches of Fig. 1 illustrate how the reduc- ing fittings are read.

ASME B16.3:2006 pdf free download