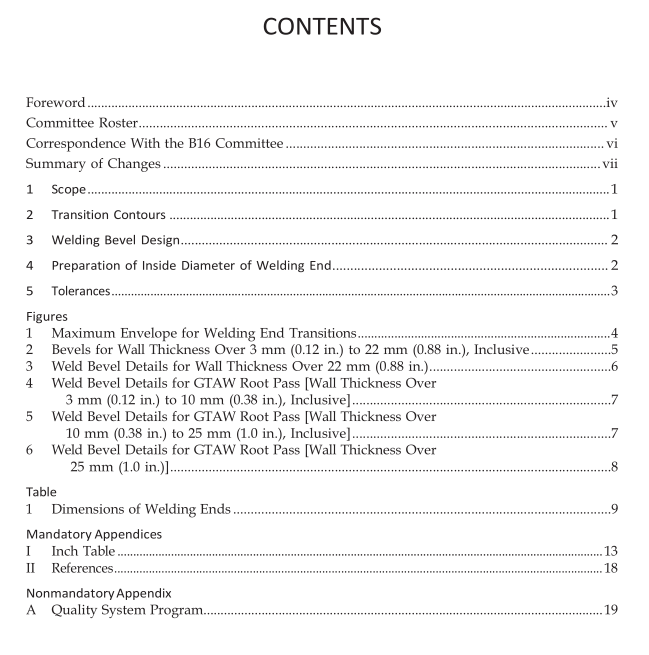

ASME B16.25:2012 pdf free download Buttwelding Ends

1 SCOPE1.1 General

This Standard covers the preparation of buttweldingends of piping components to be joined into a pipingsystem by welding. It includes requirements for weldingbevels, for external and internal shaping of heavy-wallcomponents,and for preparation of internal ends(including dimensions and tolerances). Coverageincludes preparation for joints with the following:

(a) no backing rings

(b) split or noncontinuous backing rings(c) solid or continuous backing rings(d) consumable insert rings

(e) gas tungsten arc welding (GTAW) of the root passDetails of preparation for any backing ring must bespecified when ordering the component.

1.2 Application

This Standard applies to any metallic materials forwhich a welding procedure can be satisfactorilyqualified but does not prescribe specific welding pro-cesses or procedures.Unless otherwise specified by thepurchaser, it does not apply to welding ends conformingto ASME B16.5,B16.9,or B16.47.

1.3 Relevant Units

This Standard states values in both Sl (Metric) andU.S.Customary units. These systems of units are to beregarded separately as standard. Within the text,theu.S.Customary units are shown in parentheses or in aseparate table that appears in Mandatory Appendix I.The values stated in each system are not exact equiva-lents; therefore, it is required that each system of unitsbe used independently of the other. Combining valuesfrom the two systems constitutes nonconformance withthe Standard.

1.4 Size

Nominal pipe size (NPS), followed by a dimensionlessnumber, is the designation for nominal fitting size.NPSis related to the reference nominal diameter (DN) usedin international standards. The relationship is typicallyas follows:

1.5 Referenced Standards Standards and specifications adopted by reference in this Standard are shown in Mandatory Appendix II. It is not considered practical to identify the specific edition of each standard and specification in the individual reerences. Instead, the specific edition reference is identi- fied in Mandatory Appendix II. A product made in conformance with a prior edition of referenced standards will be considered to be in conformance, even though the edition reference may be changed in a subse- quent revision of the standard.

1.6 Quality Systems Nonmandatory requirements relating to the manufacturer ’s quality system program are described in Nonmandatory Appendix A.

1.7 Convention For determining conformance with this Standard, the convention for fixing significant digits where limits (maximum and minimum values) are specified shall be as defined in ASTM E29. This requires that an observed or calculated value be rounded off to the nearest unit in the last right-hand digit used for expressing the limit. Decimal values and tolerances do not imply a particular method of measurement.

2 TRANSITION CONTOURS

Figure 1 delineates the maximum envelope in which transitions from welding bevel to the outer surface of the component and from the root face to the inner surface of the component must lie. Except as specified in Note (5) to Fig. 1, and as otherwise specified by the purchaser, the exact contour within this envelope is the manufacturer’s option, provided it maintains the specified minimum

ASME B16.25:2012 pdf free download