ASME B107-410:2008 pdf free download Struck Tools Incorporation of ASME B107.43, ASME B107.44, ASME B107.46, ASME B107.48, ASME B107.49, ASME B107.50, ASME B107.52, and ASME B107.59

1 sCOPE

This Standard provides performance and safetyrequirements for splitting wedges that are used specifi-cally for splitting wood.It is intended to serve as a guidein selecting, testing, and using the hand tools covered.lt is not the purpose of this Standard to specify thedetails of manufacturing.

This Standard is also meant to serve as a guide indeveloping manuals and posters and for training per-sonnel in safe practices.

This Standard may be used as a guide by state authori-ties or other regulatory bodies in the formulation of lawsor regulations.It is also intended for voluntary use byestablishments that use or manufacture the tools cov-ered.The methods employed to ensure compliance withthis Standard shall be determined by the proper regula-tory or administrative authority.

2NORMATIVE REFERENCES

:The following documents form a part of this Standardto the extent specified herein.At the time of publication,the editions indicated were valid.All standards are sub-ject to revision, and parties to agreements based on thisAmerican National Standard are encouraged to investi-gate the possibility of applying the most recent editionsof the documents indicated below.Copies of the publica-tions may be obtained from publishers as indicated.ANSI Z87.1-1998, Practice for Occupational EducationalEye and Face Protection

ANSI Z535.4-1998,Product Safety Signs and LabelsPublisher: American National Standards Institute(ANSI),25 West 43rd Street, New York, NY 10036ASTM E 18-00,Standard Test Methods for RockwellHardness and Rockwell Superficial Hardness ofMetallic Materials

Publisher: ASTM International (ASTM),100 Barr HarborDrive,P.O.Box C700,wWest Conshohocken,PA19428-2959

Guide to Hand Tools —Selection,Safety Tips, ProperUse and Care

Publisher: Hand Tools Institute (HTI),25 North Broad-way,Tarrytown, NY 10591

3 DEFINITIONS

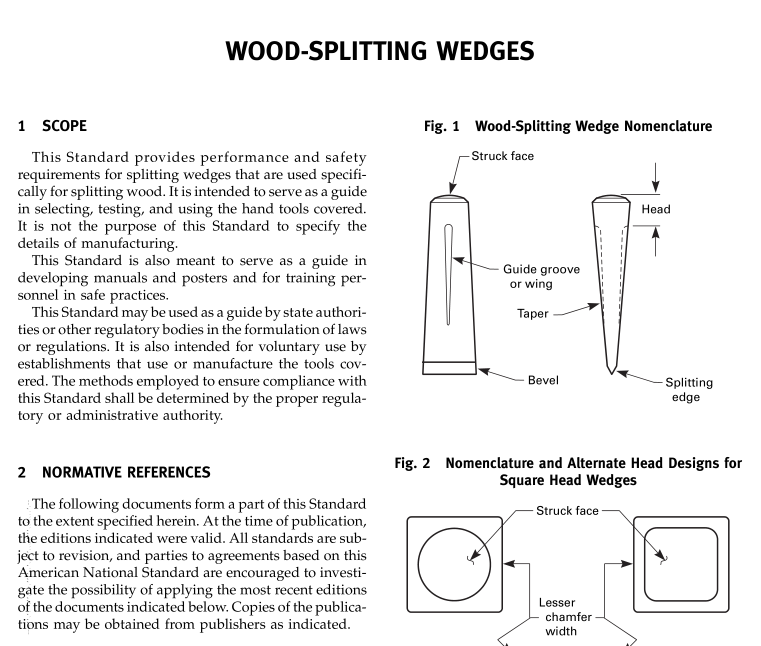

See Figs. 1, 2, and 3 as applicable. bevel: the angular portion of the wedge adjacent to the splitting edge and extending to the taper.

chamfer: the angled flat surface or equivalent radius of the wedge encircling the perimeter of the struck face. equivalent: the word equivalent in this Standard shall be interpreted to mean alternate designs or features that will provide an equal degree of safety.

guide grooves or wings: when provided, the long, narrowimpressions or protrusions located on opposite sides ofthe taper.

hardness: the condition of the wedge resulting from heattreatment.

head: the portion of the wedge between the struck faceand the taper.

safety message: the information imprinted on or affixedto the wedge that is intended to promote safety.

shall: characterizes mandatory requirements of thisStandard.

should: indicates if a provision is of an advisory nature,or is stated as a recommendation.

splitting edge: the edge formed by the bevel directly oppo-site the struck face.

struck face: the portion of the wedge located adjacent tothe head directly opposite the splitting edge.

faper: the portion of the wedge with a gradually reducingcross-sectional area, located between the head and thebevel.

REQUIREMENTS4.1 Design

Wood-splitting wedges shall have a splitting edge andtaper for splitting wood, and a struck face to be struckby the appropriate striking tool.An appropriate strikingfool shall mean a sledge or woodchopper’s maul with astriking face not less than 0.375 in. (9.50 mm) largerin diameter than the struck face of the wood-splittingwedge.

Typical styles of wood-splitting wedges are shown inFigs. 1,2, and 3, and their uses are listed below.The names are those generally recognized; however, styles are not limited to those named or illustrated.

a) The struck face shall have a flat or convex shape.(b)The struck face of all wedges shall have a chamferof approximately 45 deg (or equivalent radius) aroundthe perimeter, with the lesser width equal to approxi-mately one-tenth of the minimum head width.For exam-ple, if the minimum head width equals 2 in. (50.8 mm),then the lesser chamfer width will equal approximately0.2 in. (5 mm).

(c) All wedges shall be free of nonfunctional sharpedges, points, and surface roughness that could inflictpersonal injury on the user when handling the tool.(d) Wedges shall pass the tests outlined in section

5.4.2 Materials

The materials used in the manufacture of wedges shallbe such as to produce wedges conforming to the require-ments specified herein.

4.3 Mechanical Properties

The hardness of the wood-splitting wedges shall notexceed 35 HRC or equivalent.

5 TESTS

Many tests required herein are inherently hazardous,and adequate safeguards for personnel and propertyshall be employed in conducting such tests.

Separate (new) wedges shall be used for each test.Failure to meet the requirements of either test indicatesthat the wedges do not comply with this Standard.

5.1 Hardness Determination Test

Hardness determination shall be made on a fixturedwood-splitting wedge or on a mounted or unmountedspecimen that has been cut from the tool using the wetabrasive or other equivalent method.Any hardness testwill be acceptable that uses equipment and methodsequivalent to Rockwell hardness determination as speci-fied in ASTM E 18.

ASME B107-410:2008 pdf free download