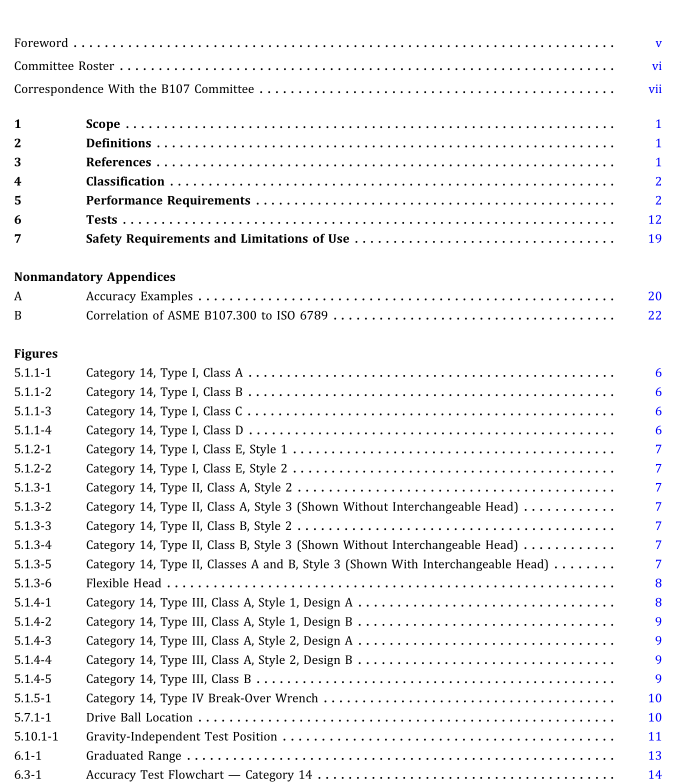

ASME B107.300:2021 pdf free download Hand Torque Tools and Torque Testers

1 scoPE

This Standard provides performance and safety re-quirements for manually operated torque instruments,commonly used for measurement of torque to controlthe tightness of threaded fasteners. lt also providesperformance and safety requirements for manually oper-ated electronic torque instruments with integral or inter-changeable heads. It includes requirements forendurance, torque value ranges,angle measurements,and accuracy for these torque instruments. It furtherprovides performance and safety requirements for elec-tronictorque testers used for checking manually operated,hand-held torque wrenches and torque screwdrivers. It isnot intended to describe products infrequently utilized orthose designed for special purposes.

This Standard may be used as a guide by state autho-rities or other regulatory bodies in the formulation of lawsor regulations. It is also intended for voluntary use byestablishments that use or manufacture the instrumentscovered.

2 DEFINITIONS

accuracy: the permissible deviation, tolerance, or errorband.A higher value means a lower certainty of correct-ness.

angle: the amount of axial rotational displacement from astart point to an end point.

break-over: a temporary reduction in torque indicating atarget value has been achieved, indicated by a displace-ment of the handle of at least 10 deg.

click: a temporary reduction in torque indicating a targetvalue has been achieved, indicated by a displacement ofthe handle of less than 5 deg.

first peak: the maximum torque value just prior to thetorque drop-off, which on Category 14, Types ll and lvtorque wrenches occurs as the wrench begins its momen-tary reduction in torque.

flex-head: see flexible ratchet head.

flexible ratchet head: a handle with the capability of oper-ating at an angle other than perpendicular to the axis ofrotation.

full scale: see rated capacity.

graduation: a mark on the instrument indicating a torquevalue.

hand torque instrument: a tool combining hand wrenchingand torque measurement functions. formerly referred toas hand torque wrench.

increment: the value of the difference between adjacentgraduations.

indicated value: for Category 14,Type l, the value theinstrument displays when torque is applied; for TypesII,I1I,and lv, the value to which the instrument is setor preset.

measured value: the actual torque determined by a torquetester.

operating load: the operating load shall be calculated bydividing the rated capacity by the distance between theaxis of the torque moment and the center of the grip ordesignated load point.

peak: the maximum torque value reached during theprocess of applying the load to the wrench.

pivot: a short rod or shaft on which a related part rotates orswings.

rated capacity: the maximum intended torque the usershall measure or apply.

resolution: the smallest distinguishable change indisplayed value.

scale: the representation of the range of the instrument,divided into increments marked by numbered andunnumbered graduations.

setting: the amount of torque the instrument is expected toapply.

torque-to-angle: a method of assembly where a thresholdtorque is applied and then more torque is applied toproduce a specific angle.

track: continuous readout of torque applied at anymoment.

usable range of the transducer: the range to which theaccuracy requirements of para.5.9 are applied.

3 REFERENCES

The following documents form a part of this Standard tothe extent specified herein.The latest edition shall be used.ASMEB107.4, Driving and Spindle Ends for Portable Hand,lmpact,Air, and Electric Tools (Percussion ToolsExcluded)

4 CLASSIFICATION

See Tables 4-1,4-2, and 4-3.

5 PERFORMANCE REQUIREMENTS

Figures are descriptive and not restrictive.They are notintended to preclude the manufacture or purchase ofotherforms of torque instruments conforming to this Standard.Torque instruments shall pass all applicable tests insection 6.

Unless otherwise specified, torque instruments shall becalibrated in the direction(s) of intended use.

Torque instruments shall be capable of being calibratedto the specified accuracy by a method traceable to theNational Institute of Standards and Technology (NIST).5.1 Design – Category 14 Mechanical

5.1.1 Type l, Classes A, B, C, and D – Indicating(a) Operation. Instruments shall indicate torqueapplied through a deflecting member. They shall

operate in both clockwise andgmember. They shalltions.

(1) Type I, Classes A and B—Deflecting Beam. Flexingof a cantilever beam connecting the square drive and handgrip shall provide the basis of operation.Type I, Class Adeflecting beam torque instruments may be similar to thatshown in Figure 5.1.1-1.Type I, Class B deflecting beamtorque instruments may be similar to that shown in Figure5.1.1-2.

(2)Type 1, Classes C and D — Rigid Housing. Thedeflecting member and dial mechanism shall be enclosedwithin the rigid housing.The pointer and dial face shall beprotected by a transparent cover that shall be so locatedand constructed as to be reasonably free from accidentaldamage resulting from being struck or abraded. Type l,Class C rigid housing torque instruments may besimilar to that shown in Figure 5.1.1-3.Type l,Class Drigid housing torque instruments may be similar tothat shown in Figure 5.1.1-4.

ASME B107.300:2021 pdf free download