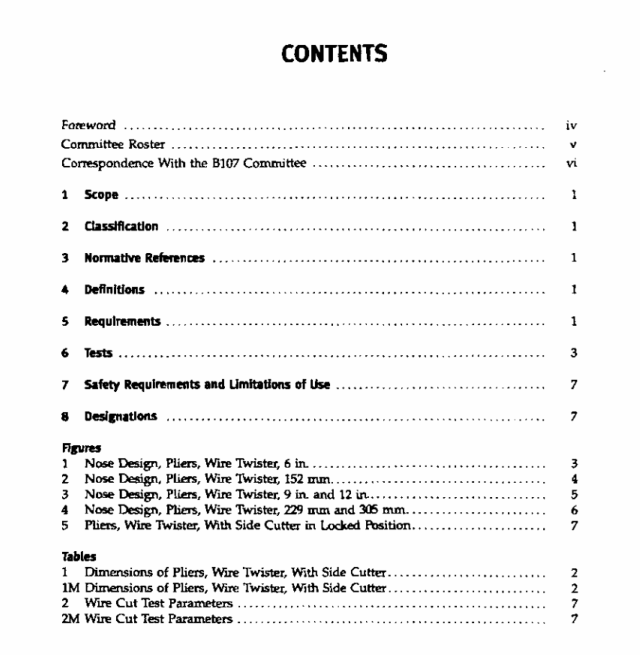

ASME B107.18:2003 pdf free download PLIERS: WIRE TWISTER

Wre twister pliers shall incorporate a device, which,when actuated, wili cause the plers to rotate about itslongitudinal axis. The halves of the plers shall be perna-neitly joined with a through fastener that shali act asthe pivot or fulcrum point of the pliers. A locking device.when engaged, shali hold the handles in a closed posi-tion in such a marner as to cause the jaws to firmly andsecurely grip and hold strands of lock wire.

A wire clearance openinrg shall be provided betweenthe two jaws and located between the gripping andcutting areas of the jaws. This opening shall be of a sizeand design which wil perurut the user to swiftly andeasily deflect double strands of wire out af the sides ofe jaws and away fron the cutting edges when per-forming continuous (multiple) lock wiring operatians.The nose design shall be a5 shown in Figsi 1 through 4and blerd with the radius of the sides of the pliers inaccordance with good connercial practice. “The maxi-mun pernissible opening at the top of the jaws, whenclosed, shall be as shown in Figs. 1 and2

5.2 Materlal

The rraterials used in the marufacture of the pliessshall be such as to produce pliers conforning to therequirements specified herein.

5.3 Finish

Surfaces shall have a hust preventive treatment andbe essentially free fron pits, nodules,bufTs, cracks,andother conditions that would adversely affect the per-formance or safety of the tool. When provided, coatingsshall be adherent.smooth, continuous,and free fromany conditions that would inteifere with their prstectivevalue, safety, and function.

Phers shail be marked in a plain and permanent nan-ner with the manufacturer’s nane or with a tademarkof such known character that the source of manufactureand country of origin shall be readily determined.Mark-ing shall be as pertranent as the nortal life expectancyof the pliers to whichit is applied (providing the markedsurface has not been subjocted to a fretting or abradingaction) and be capabie of withstanding the ceaning procedures riormally experierced during its intended use.5.5 Handles

Handles shall have a hardness of 36 HRC to 50 HRC.shall be shaped to provide a comfortable handgrip, andshall be free fron rough edges and sharp corRlers.

5.6 jaws

5.6.1 Hardness. Jaws shaill have a hardness of 361RCto 50 HRC.The gripping portion of the jaws and wirecutter shall be heat treated to a hardness of 56 HRC to64HRC. Jaw surfaces and edges shal not damage thewie being twisted.

5.6,2 Cushlan 6rip Throat.Cushion grip throat whenprovided,shall grip and retain cut wire end. The cushiongrip throat shal be nonmetallc and capable of with-starding nocaal use without deteriorating or rubbingoff and shall pass the solvert resistance tesi in para.6.4Cushion grip throat shall renain permanently attachedurder normal use.

5.7 Jolnt Fastenexr

The fasterer shall have a hardness of 25 HRC to 50HRC

5.8 Spir il Mechanlsm

The spiral mechanismn shall be capable of producinga close, uniform twist in safety wire without binding oior danage to the amachanisr. This mechanism shali bemounted between the handles of the pliers and shall beperanently affixed to one handle in such a poaitionthat the longitudinal axis of the echanismn shall corre-spond to the langitudinal axis of the pliers.The mecha-nism, when achated, shall cause pliers to rotate aboutits longitudinal axis in its intended directian(s). Fachfuliactuation of the unechanism shall cause the pliersto ake the following minimum nurnber of comipleterotations:

a)for 6 in. (152 mm) size,2lrotations (with auto-matic rehun, 2 rotations)

(bfor9 in. [229 mn) size,3 rotations (with autoaticretun, 25rotations)

ffor 12 in.(305 am) size,4rotations (with automaticreturn,31rotations) (iype l Reversibie, 3 rotatiors)The design of the ‘uiechanism shal permit a comfort-able, adequate grip by the operator.

ASME B107.18:2003 pdf free download