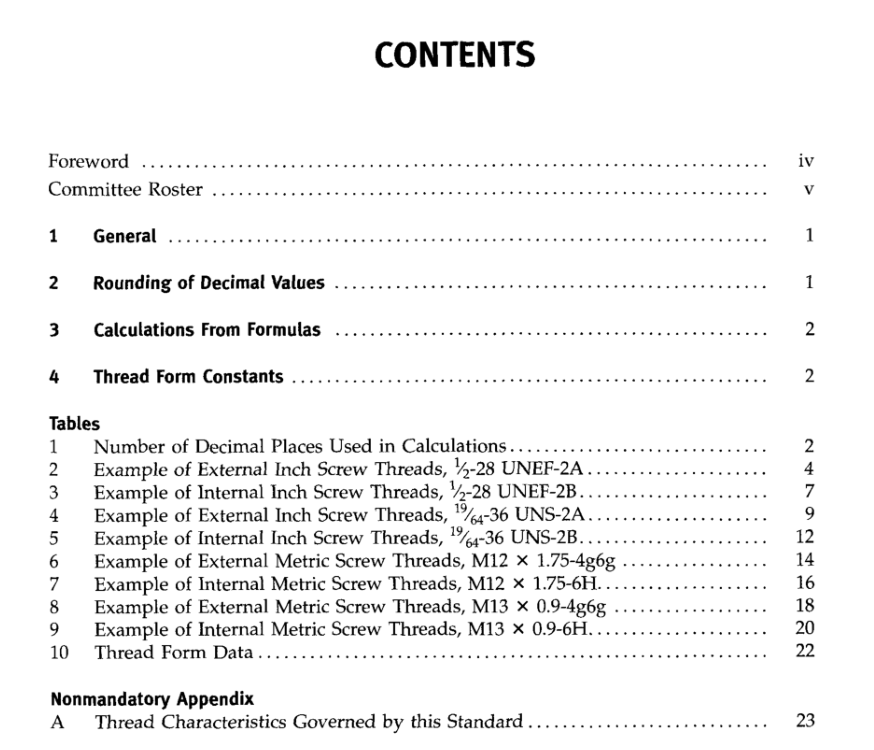

ASME B1.30:2002 pdf free download SCREW THREADS:STANDARD PRACTICEFOR CALCULATINGAND ROUNDING DIMENSIONS

1 GENERAL

1.1 Purpose The purpose of this Standard is to establish uniform and specific practices for calculating and rounding the numeric values used for inch and metric screw thread design data dimensions only. No attempt is made to establish a policy of rounding actual thread characteris- tics measured by the manufacturer or user of thread gages. Covered is the Standard Rounding Policy regard- ing the last figure or decimal place to be retained by a numeric value and the number of decimal places to be retained by values used in intermediate calculations of thread design data dimensions. Values calculated to this Standard for inch and metric screw thread design data dimensions may vary slightly from values shown in existing issues of ACME B1 screw thread standards and are to take precedence in all new or future revisions of ASME B1 standards as applicable except as noted in para. 1.2.

1.2 Metric Application Allowances (fundamental deviations) and tolerances for metric M and MJ screw threads are based upon formulas, which appear in applicable standards. Values of allowances for standard tolerance positions and val- ues of tolerances for standard tolerance grades are tabu- lated in these standards for a selection of pitches. Rounding rules specified below have not been applied to these values but have followed practices of the Inter- national Organization for Standardization (ISO). For pitches, which are not included in the tables, standard formulas and the rounding rules specified herein are applicable. NOTE: IS0 rounding practices, for screw thread tolerances and allowances, use rounding to the nearest values in the R40 series of numbers in accordance with IS0 3. in some cases, the rounded values have been adjusted to produce a smooth progression. Since the IS0 rounded values have been standardized internationally, for metric screw threads, it would lead to confusion if tolerances and allowances were recalculated using B1.30 rules, for use in the USA. 81.30 rounding rules are, therefore, only applicable to special threads where tabulated values do not exist in IS0 standards. Values calculated using the IS0 R40 series values may differ from those calculated using 81.30. in such a case the special thread values generated using 81.30 take precedence.

2 ROUNDING OF DECIMAL VALUES

The following rounding practice represents the method to be used in all new or future revisions of ASME B1 thread standards.

NOTE: It is recognized that this Standard is not in agreement with other published documents, e.g., ASME SI-9, Guide for Metrication o? Codes and Standards SI (Metric) Units, and IEEE/ASTM SI 10, Standard for Metric Practice. The rounding practices used in the forenamed documents are designed to produce even distribution of numerical values. The purpose of this document is to define the most practical and common used method of rounding numerical thread form values. Considering today?s technology, application of this method is far more practical in the rounding of thread form values.

2.1 Rounding Policy

When the figure next beyond the last figure or place retained is less than 5, the figure in the last place retained is kept unchanged.

2.1.2 When the figure next beyond the last figure or place retained is greater than 5, the figure in the last place retained is increased by 1.

2.1.3 When the figure next beyond the last figureor place retained is 5, and:

a) there are no figures, or only zeros, beyond this 5,the last figure should be increased by 1;

(b) if the 5 next beyond the figure in the last place to be retained are followed by any figures other than zero,the figure in the last place retained should be increased by 1

2.1.4 The final rounded value is obtained from the most precise value available and not from a series of successive rounding. For example, 0.5499 should be rounded to 0.550, 0.55 and 0.5 (not 0.6), since the most precise value available is less than 0.55. Similarly, 0.5501 should be rounded as 0.550,0.55 and 0.6, since the most precise value available is more than 0.55. In the case of 0.5500 rounding should be 0.550,0.55 and 0.6, since the most precise value available is 0.5500.

ASME B1.30:2002 pdf free download