ASME B1.3:2017 pdf free download Screw Thread Gaging Systems for Acceptability: Inch and Metric Screw Threads (UN, UNR, UNJ, M, and MJ)

1GENERAL

(a)This Standard presents screw thread gaging sys-tems suitable for determining the acceptability of UN,UNR,UNJ,M, and MJ screw threads on externally andinternally threaded products. It establishes the criteriafor screw thread acceptance when a gaging system isused.

(b)A screw thread gaging system comprises a list ofscrew thread characteristics that must be inspected/evaluated to establish the acceptability of the screwthreads on a threaded product and the gage(s) whichshall be used when inspecting/evaluating those charac-teristics.

(c) Federal Government Use.This Standard is

approved by the Department of Defense and federalagencies, and is incorporated into FED-STD-H28/20,screw Thread Standards for Federal Services, Section20.The use of this Standard by the federal government

is subject to all the requirements and limitations ofFED-STD-H28/20.

2 REFERENCE DOCUMENTS

The latest issues of the following documents form apart of this Standard to the extent specified herein.ASME B1.1,Unified Inch Screw Threads (UN and UNRThread Form)1

ANSI/ASME B1.2,Gages and Gaging for Unified InchScrew Threads1

ASME B1.7,Screw Threads: Nomenclature,Definitions,and Letter Symbols1

ASME B1.13M,Metric Screw Threads: M ProfilevASME B1.15,Unified Inch Screw Threads (UNJ ThreadForm)

ANSI/ASME B1.16M,Gages and Gaging for Metric MScrew Threads1

ASME B1.21M,Metric Screw Threads: MJ Profile1ANSI/ASME B1.22M, Gages and Gaging for MJ SeriesMetric Screw Threads1

ASME B46.1,Surface Texture (Surface Roughness,Waviness, and Lay)1

ASME/ANSI B47.1,Gage Blanks1

Publisher: The American Society of MechanicalEngineers (ASME)。Three Park Ave,New York,NY10016-5990; Order Department: 22 Law Drive,Box2300,Fairfield, NJ07007-2300

3 SCREW THREAD GAGES AND MEASURING

EQUIPMENT

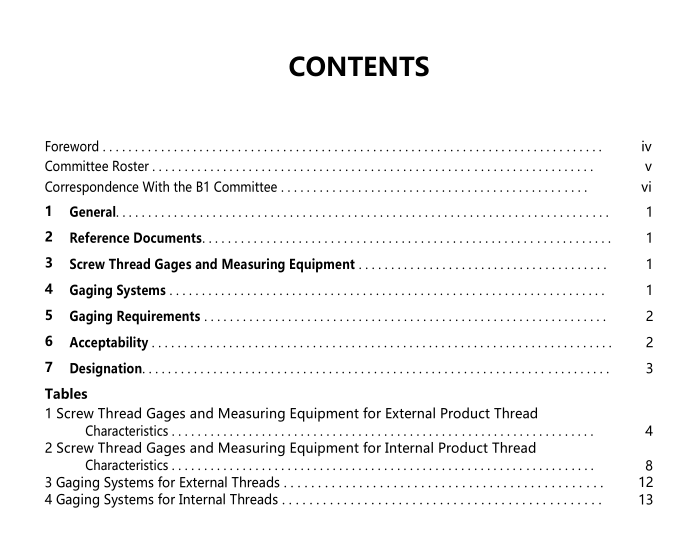

(a)Tables 1 and 2, for external and internal screwthreads, respectively, are listings of screw thread gages,gaging elements, and measuring equipment.

NOTE: Throughout the remainder of this Standard, the term gageincludes any gages, gaging elements, and measuring equipmentlisted in Tables 1 and 2.See para. 5(d).

For each gage, these tables specify the thread charac-teristic(s) for which the gages are designated for

determining conformance.

(b)The tables are arranged to establish product screwthread acceptance criteria based on recognized gagingconcepts used to assess conformance.

(i) Attributes. Fixed limit inspection/evaluationprovides a qualitative assessment of a characteristic(s)using gages which determine conformance.

(2Variables. Indicating control is a quantitativeand qualitative assessment on a characteristic(s) whichis then compared with limiting values in order to deter-mine if the characteristic(s) is in conformance.

4 GAGING sYSTEMS

(a)Tables 3 and 4 present screw thread gaging sys-tems for inspection/evaluation of externally and inter-nally threaded products, respectively.

(b)Three gaging systems for inspection/evaluationof threads on threaded products are established hereinto provide a choice depending on the engineeringrequirement of the threaded product.These are identi-fied as Systems 21,22,and 23.The difference betweengaging systems is the level of inspection/evaluationdeemed necessary to satisfy that conformance has beenachieved.

(c) Since most screw thread applications do notrequire that all of the characteristics described in the applicable product specifications, standards, and appli- cations documents be inspected/evaluated, selection of the appropriate gaging system will be based on those characteristics important to the end use. Consideration should be given to such factors as form, fit, function, and fabrication of the threaded product. Measurement/ gage design capabilities inherent in each inspection/ evaluation system should also be considered when com- paring the benefits of each system. Guidance for selec- tion of an inspection/evaluation system from the three established gaging systems is as follows:

(1 ) System 21 . Provides for interchangeable assem- bly with functional size inspection/evaluation at the maximum material limit within the length of standard gaging elements, and also inspection/evaluation of characteristics identified as NOT GO functional diame- ters or as HI (internal) and LO (external) functional diameters. (2) System 22. Provides for interchangeable assem- bly with functional size inspection/evaluation at the maximum material limit within the length of standard gaging elements, and also inspection/evaluation of the minimum material size pitch diameter or thread groove diameter over the length of the full thread. The cumula- tive effects of all other thread characteristics such as lead, flank angle, taper, and roundness variations are confined within product tolerance limits with no specific inspection/evaluation of their magnitudes.

ASME B1.3:2017 pdf free download