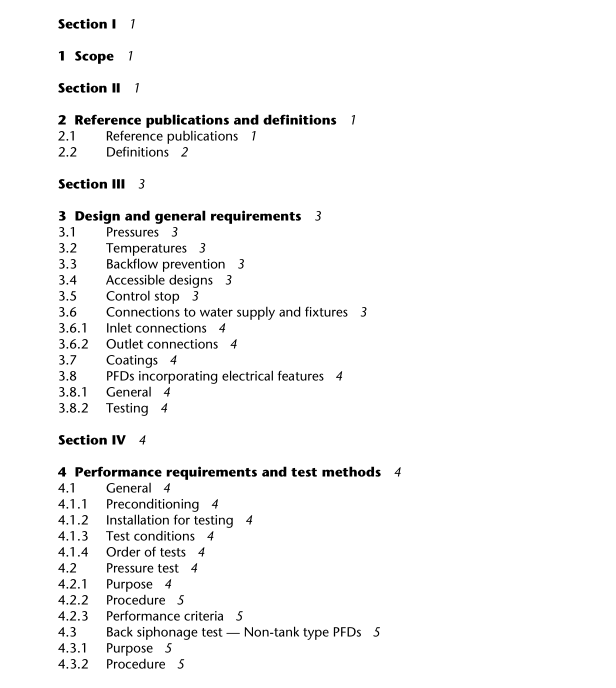

ASME A112.1037:2015 pdf free download Performance requirements for pressurized flushing devices for plumbing fixtures

1 Scope

1.1

This Standard covers pressurized flushing devices (PFDs) intended to flush water closets, urinals, and otherplumbing fixtures and specifies requirements for materials, design, methods of operation, test methods,and markings.

1.2

In this Standard, ” shall” is used to express a requirement, i.e., a provision that the user is obliged to satisfyin order to comply with the standard; “should”is used to express a recommendation or that which isadvised but not required; and “may” is used to express an option or that which is permissible within thelimits of the standard.

Notes accompanying sections do not include requirements or alternative requirements; the purpose of anote accompanying a section is to separate from the text explanatory or informative material.

Notes to tables and figures are considered part of the table or figure and may be written asrequirements.

Annexes are designated normative (mandatory) or informative(non-mandatory) to define theirapplication.

1.3

Sl units are the units of record in Canada. In this Standard the inch/pound units are shown in parentheses.The values stated in each measurement system are equivalent in application; however, each system is tobe used independently.Combining values from the two measurement systems can result in

non-conformance with this Standard.All references to gallons are to U.s. gallons.

Section lI

Reference publications and definitions2.1 Reference publications

This Standard refers to the following publications, and where such reference is made, it shall be to theedition listed below, including all amendments published thereto.

ASME (The American Society of Mechanical Engineers)/CSA Group

ASME A1 1 2.1 8.1 -201 2/CSA B1 25.1 -1 2

Plumbing supply fittings

ASME A1 1 2.1 9.2-201 3/CSA B45.1 -1 3

Ceramic plumbing fixtures

ASME (The American Society of Mechanical Engineers)

A1 1 2.1 8.3-2002 (R201 2)

Performance requirements for backflow protection devices and systems in plumbing fixture fittings A1 1 2.1 9.1 4-2006 (R201 1 )

Six-liter water closets equipped with a dual flushing device

B1 .1 -2008

Unified Inch Screw Threads (UN & UNR Thread Form)

B1 .20.1 -201 3

Pipe Threads, General Purpose (Inch)

B1 6.1 8-201 2

Cast Copper Alloy Solder Joint Pressure Fittings

B1 6.22-201 3

Wrought Copper and Copper Alloy Solder Joint Pressure Fittings

ASSE (ASSE International Chapter of IAPMO, LLC.)

1 001 -2008

Performance Requirements for Atmospheric Type Vacuum Breakers

Plumbing Dictionary Sixth Edition — 2007

CSA Group

B64 Series-1 1

Backflow preventers and vacuum breakers

B64.1 .1 -1 1

Atmospheric vacuum breakers (AVB)

SAE International (Society of Automotive Engineers)

J51 2 (1 997)

Automotive Tube Fittings

2.2 Definitions

In addition to the definitions in the reference publications, the following definitions shall apply in this Standard:

Back siphonage — backflow caused by below-atmospheric pressure in the water system.

Backflow — a flowing back or reversal of the normal direction of flow.

Note: Back siphonage and back pressure are types of backflow.

Critical level (CL) — the lowest water level in a fitting at which back siphonage will not occur.

Pressurized flushing device — a device that utilizes the water supply pressure to flush plumbingfixtures.

Non-tank type PFD (Flushometer valve)— a pressurized flushing device that is attached to apressurized water supply pipe that, when actuated, opens the pipe for direct flow of water into thefixture at a rate and in a quantity that enables proper operation of the fixture.The valve then

gradually closes to provide trap reseal in the fixture and avoid water hammer.

Tank type PFD (Flushometer tank)— a pressurized flushing device in a pressurized water supplypipe but integrated within an accumulator vessel affixed and adjacent to the fixture inlet to cause aneffective enlargement of the supply line. The discharge directs the flow of water into the fixture at arate and in a quantity that enables proper operation of the fixture. The valve then gradually closes toprovide trap reseal in the fixture and avoid water hammer.

Primary control- the standard means by which the PFD is activated as designated by themanufacturer.

Secondary control-an alternative means by which the PFD is activated as designated by themanufacturer.

Section II

3 Design and general requirements

3.1 Pressures

PFDs shall be designed to function at a supply pressure between 140 and 860 kPa (20 and 125 psi). lnaddition,PFDs shall comply with Clause 4.2.

3.2 Temperatures

PFDs shall be designed to function with water temperature between 4 °C and 30 °C(40°F and 85°F).

3.3 Backflow prevention

PFDs incorporating backflow preventers shall comply with the requirements of Clause 4.3 or 4.4.When abackflow preventer is not incorporated in the PFD, installation instructions shall identify the specific typesof backflow prevention required.

ASME A112.1037:2015 pdf free download