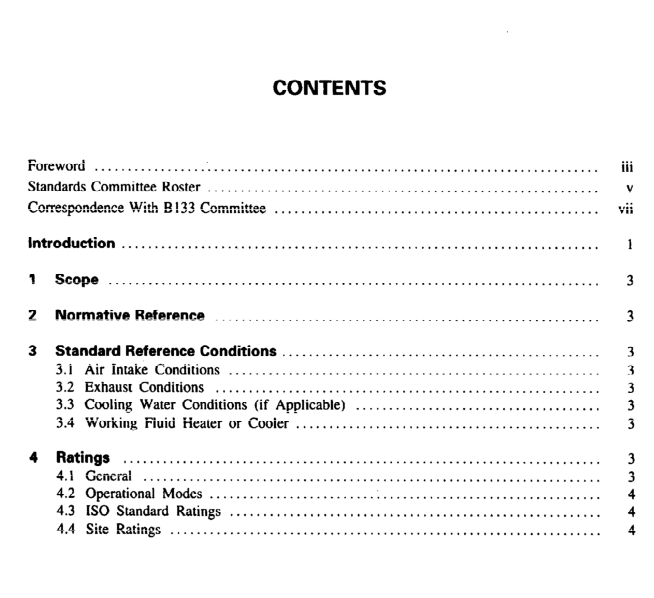

ASME 3977-2:2000 pdf free download GAS TURBINES:PROCUREMFNT Papt 2: Standard Reference Conditions and Ratings

scoPE

This Part of ASME 3977 specifics the standardreference conditions and lso standard ratings for gasturbines.

2 NORMATIVE REFERENCE

The following standard contains provisions which,through rcfcrcncc in this text,constitute provisions ofthis Part of ASME 3977.At thc timc of publication,the edition indicated was valid.All standards are subjectto revision,and parties to agreements based on thisPart of ASME 3977 are encouraged to investigate thepossibility of applying the most recent edition of thestandard indicated below.

IsO 2314: 1989,Gas turbines — Acceptance Tests.

3 STANDARD REFERENCE CONDITIONS

The standard reference conditions on which power,efficiency, heat rate, and specific fuel consumption arebased are as specified in 3.1 through 3.4.

3.1 Air Intake Conditions

For the intake air at the compressor flange (alterma-tively,the compressor intake flare),as described inIso 2314: 1989,6.6.2,the conditions shall be:

(a) a total pressure of 101.3 kPa (14.696 psia);(b) a total temperature of 15c (59°F);

(c) a relative humidity of 60%.

3.2 Exhaust Conditions

For the exhaust at the turbine exhaust flange (orregenerator outlet, if a regenerative cycle is used),thestatic pressure shall be 101.3 kPa (l4.696 psia).

3.3 Cooling Water Conditions (if Applicable)The inlet water temperature shall be 1s°c (5oF) ifcooling of the working fluid is used.

3.4Working fFluid Heater or Cooier

Whcre a heater or a cooler is used that uses arnbientair,the standard reference conditions of the ambientair shall be 15°c (59r) and 1O1.3 kPa (14.696 psia).

4RATINGS

4.1 Generai

4.1.1 The output power of a given gas turbine aia givcn reference turbine inlet temperature is, in general,proportional to the absolutc ambicnt pressure and isalso greatly dependent on the air intake tempcraturc(normally outside dry bulb temperature). Likewise,theoutput at a given air intake temperature is dependenton the reference turbine inlet temperature.To achievea rating. it is necessary to adopt standard conditionsof ambient temperature and pressure,but gas turbineratings wili nevertheless vary considerably owing tothe differing operational modes demanded of them aswell as the varying criteria used in the design of thebasic eiements. iSO standard ratings negiect pressuredrup at the inlet and exhaust but site ratings aiiow forthese losses.

NOTE: Steam or water injection may be used to increase the poweroutput and to reduce the Noemissions.

4.1.2 Thc performancc ratings of gas turbincs shallbe assessed on the nct spccific cncrgy of the fuel used,as follows:

a; turbines intended for use on liquid fuel:42 000kJ/kg (18,060 btu/1bm);

turbines intended for use on gaseous fuel (100%methane): 50 000 kJ/kg (21,500btu/lorm).

The specific energy at constant pressure of the fuel,whcther liquid, gascous, or solid, is based on a pressureof 10I.3 kPa (14.696 psia) and a temperature of 15°c(59°F).

4.1.3 If the fuel to be used for testing the gas turbineis different from that agreed between the purchaser andthe manufacturer for service operation,a test fuel ofa mutually agreed specification shall be used.

NOTE: Further information will be given in Iso 3977-4,now incourse of preparation.

4.2 Operationai Modes

Unless specially agreed upon between the purchaserand the manufaciurer,the net power rating of a gasturbinc shall be specified under a combination of oneof the classcs specified in 4.2.1 togcthcr with onc ofthc rangcs of avcragc numbcr of starts pcr annumspecified in 4.2.2.

EXAMPLE: B (Class B,Rangc ) rcfcrs to opcration of up to2 00O h per annum associated with any number of starts up to 5oMnper annum.

The manufacturer shall state the type, frequency, anddcgrcc of inspection and/or maintcnancc required forthe relevant operational mode.

NOTE: Further information will be givcn in IsO 3977-4,now incourse of preparation.

4.2.1 Classes

(a)Class A: operation up to and including 500 hper annum at reserve peak power rating.

(b)Class : operation up to and including 2 00O hper annum at peak power rating.

(c)Class C: operation up to and including 60) hper annum at semi-base power rating.

(dy Class D: operation up to and inclding 8 760 hper annum at base power rating.

ASME 3977-2:2000 pdf free download