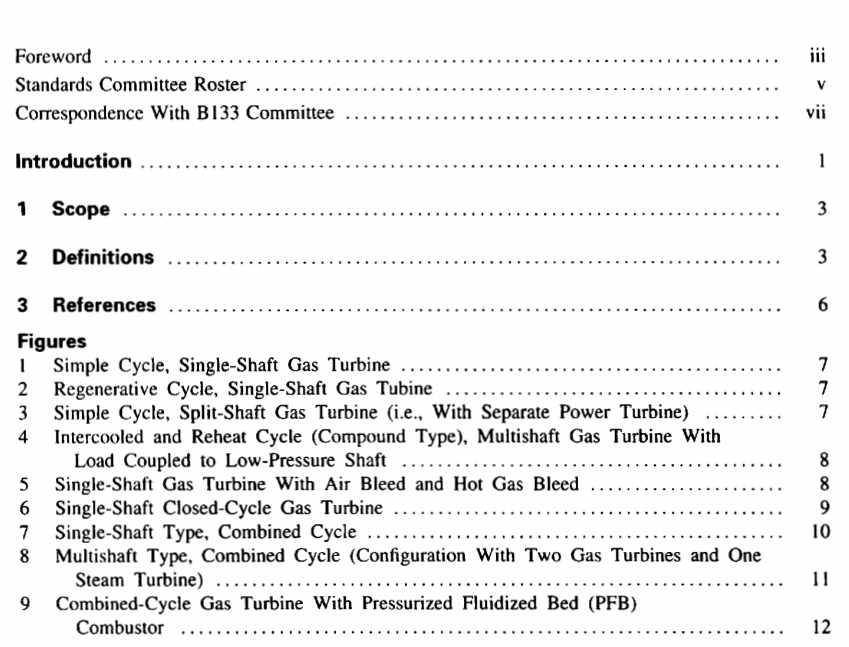

ASME 3977-1:2000 pdf free downloadGAS TURBINES:PROCUREMENT Part 1: General Introductionand Definitions

1 scoPE

This Part of ASME 3977 groups together the termsand definitions given in tso 11086 that are relevantto the procurement of gas turbine systems, and definesadditional terms.

2 DEFINITIONS

For the purposes of all parts of ASME 3977,thefoliowing definitions apply.

2.1

gas turbine: machine which converts thermal energyinto mechanical work; it consists of one or severalrotating compressors,a thermal device(s) which heatsthe working fluid,one or several turbines,a controlsystem,and essential auxiliary equipment. Any heatexchangers (excluding waste exhaust heat recovery ex-changers) in the main working fluid circuit are consid-ered to be part of the gas turbine.

NOTE:Examples of gas turbine systems are shown in Figs. 1through 9.

2.2

gas turbine power plant:gas turbine engine and allessential equipment necessary for the production ofpower in a useful form (e.g., electrical,mechanical,orthermal). [IsO 11086]

2.3

open cycle:thermodynamic cycle in which the work-ing fluid enters the gas turbine from the atmosphereand is discharged into the atmosphere. [ISO 11086]2.4

closed cycle:thermodynamic cycle having a recirculat-ing working fluid independent of the atmosphere. [ISo1 1086]

2.5

semictosed cycle: thermodynamic cycle utilizing com-bustion in a working fluid that is partially recirculatedand partially exchanged with atmospheric air. [ISo11086]

2.6

simple cycle:thermodynamic cycle consisting only ofsuccessive compression,combustion,and expansion.[ISo 11086]

2.7

regenerative cycle: thermodynamic cycle employingexhaust heat recovery, consisting of successive compres-sion,regenerative heating,combustion,expansion, andregenerative cooling (heat transfer from the exhaust tothe compressor discharge fluid) of the working fluid.[ISO 11086]

2.8

intercooled cycle: thermodynamic cycle employingcooling of the working fluid bctween stages of succes-sive compression. [ISO 11086]

2.9

reheat cycle:thermodynamic cycle employing the ad-dition of thermal energy to the working fluid betweenstages of expansion.

2.10

combined cycle: thermodynamic cycle employing thecombination of a gas turbine cycle with a steam orother fluid Rankine cycle.

NOTES:

(l) In a cormmon example,the gas turbine exhaust heat is usedto generate sleam for the Rankine cycle.

(2) The superior thermal performance of this cycle is due to acombination of the best thermodynamic attributes of each cyele.

namely the addition of thermal energy at higher temperatures in thegas turbine cycle and the rejcction of thermal energy atlowertemperatures in the Rankine cycle. [ISO 11086]

2.11

single-shaft gas turbine:gas turbine in which thecompressor and turbine rotors are mechanically coupledand the power output is taken either directly or throughgearing.

2.12

multishaft gas turbine:gas turbine combination includ-ing at least two turbines working on independent shafts.NOTE: The term includes cases referred to as compound and split-shaft gas turbines.

2.13

bled gas turbine:gas turbine which has,for externaluse,extraction of compressed air between compressorstages and/or al the discharge of the compressor,orextraction of hot gas at the inlet of the turbine and/or between turbine stages.

2.14

gas generator: assembly of gas turbine componentsthat produces heated pressurized gas to a process orto a power turbine.

NOTE: It consists of one or more rotating compressoris). thermaldevice(s) associated with the working fluid , and one or more compres-sor-driving turbine(s). a control system and essential auxiliary equip-ment.[ISO 11086]

2.15

compressor: that component of a gas turbinc whichincreases the pressure of the working fluid.

2.16

turbine: term which when used alone refers to theturbine action only. It is that component of the gasturbine which produces power from expansion of theworking fluid.

ASME 3977-1:2000 pdf free download