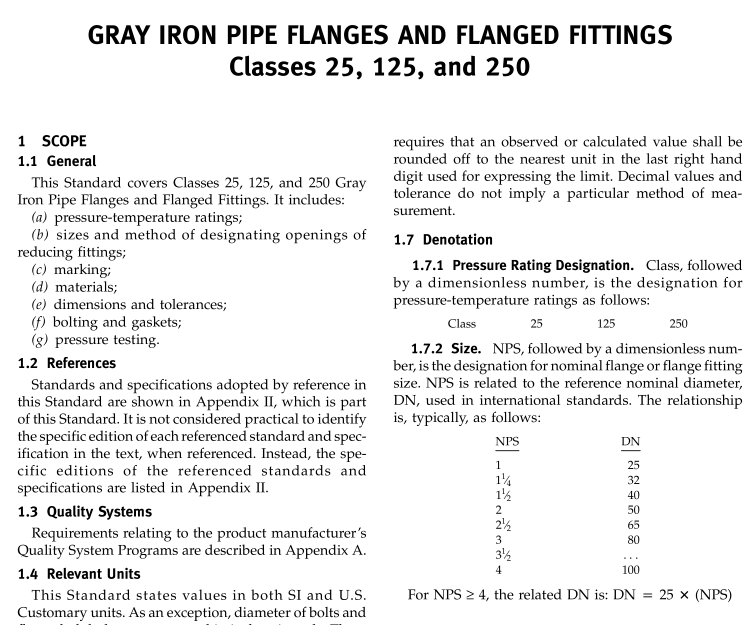

ASME B16.1:2005 pdf free download Gray Iron Pipe Flanges and Flanged Fittings (Classes 25, 125, and 250)

Bolting ASTM A307 Grade B bolting material is recommended forgrayiron flange assembly. Where grayiron flanges are bolted to steel flanges, see ASME B16.5 for bolting limita- tions. 7 FITTING DIMENSIONS AND TOLERANCES 7.1 Wall Thickness It is recognized that some variations are absolutely unavoidableinthemakingofpatternsandcastings.Equip- ment shall be designed to produce wall thicknesses given in the tables. Wall thickness at no point shall be less than 87.5% of the thickness given in the tables.

7.2 Facing (a) Classes 25 and 125 gray iron flanges and flanged fittings shall be flatfaced (i.e., withoutprojectionorraised face) and finished in accordance with MSS SP-6. (b) Class 250 flanges and flanged fittings shall have a 2 mm (0.06 in.) raised face of the diameters given in Table 7.6.1-3 and finished in accordance with MSS SP-6. The raised face is included in the minimum flange thickness and center-to-face dimension. 7.3 Center-to-Face Dimensions

7.3.1 Side Outlet Fittings. Side outlet elbows, side outlet tees, and side outlet crosses shall have all openings on intersecting centerlines. Long-radius elbows with side outletshall have the side outleton the radial centerline of the elbow.

7.3.2 Elbows

(a) The center-to-face dimensions for straight-size 90- deg elbows, 90-deg long-radius elbows, 45-deg elbows, side-outlet 90-deg elbows, and double-branch elbows are shown in Tables 7.3.2-1 through 7.3.2-5.

(b) Reducing 90-deg elbows, reducing 90-deg long- radius elbows, reducing side-outlet 90-deg elbows, and reducing double-branch elbows shall have the same center-to-face dimensions as straight-size fittings shown in Tables 7.3.2-1 through 7.3.2-3 corresponding to the size of the largest opening.

(c) For 90-deg long-radius elbows with side outlet, the center-to-face dimensions of the side outlet shall be the sameasdimensionAinTables7.3.2-1 through7.3.2-3 fora straight-size90-degelbowcorrespondingtothesizeofthe largest opening.

(d) Special-degreeelbowsrangingfrom1 degto45 deg, inclusive, shall have the same center-to-face dimensions as those for45-degelbows; those over45 degand up to 90 deg, inclusive, shall have the same center-to-face dimen- sions as those for 90-degelbows. The angle designation of an elbow is the angle between the flange faces.

7.3.3 Tees, Crosses, and Laterals

(a) Thecenter-to-facedimensionsforstraight-sizetees and crosses, with or without side outlet, and laterals are shown in Tables 7.3.2-1 through 7.3.2-3.

(b) Reducing tees and reducing crosses, with or without side outlet, and reducing laterals, NPS 16 and smaller, shall have the same center-to-face dimensions as straight-size fittings shown in Tables 7.3.2-1 through 7.3.2-3 corresponding to the size of the largest opening. For NPS 18 and larger, ifthe outlet ofa reducing tee; thebranchofareducinglateral; orthelargestoutletof a reducing side outlet tee, reducing cross, and reducing side outlet cross is the same size or smaller than given in Tables 7.3.2-1 through 7.3.2-3 (short-body pattern), the center-to-face dimensions shown in these Tables shall be used. If a branch or any outlet is larger than shown in Tables 7.3.2-1 through 7.3.2-3, the center-to- face dimensions shall be the same as for the straight- size fitting shown in Tables 7.3.2-1 through 7.3.2-3 corre- sponding to the size ofthe largest opening. Tees, crosses, and laterals, reducingon the run only, shall have the same center-to-face dimensions as straight-size fittings shown inTables 7.3.2-1 through7.3.2-3 correspondingto thesize of the largest opening.

(c) Tees reducing on both runs are generally known as bull-head tees and have the same center-to-face dimen- sions as straight-size fittings corresponding to the size of the outlet.

7.3.4 True Y’s. Center-to-face dimensions for straight- size true Y’s are shown in Tables 7.3.2-2 and 7.3.2-3. Re- ducingsizes are considered special and should be made to suit conditions.

7.3.5 Reducers and Eccentric Reducers. The face-to- face dimensions for all reductions of reducers and eccentric reducers shall be the same as given in Tables 7.3.2-2 and 7.3.2-3 for the largest opening.

7.4 Center-to-Face Tolerances The following tolerances shall be permitted on all center-to-contact surface dimensions of fittings. Toler- ances for contact surface-to-contact surface dimensions shall be twice those given below. The largest opening in the fitting governs the tolerance to be applied to all openings.

ASME B16.1:2005 pdf free download