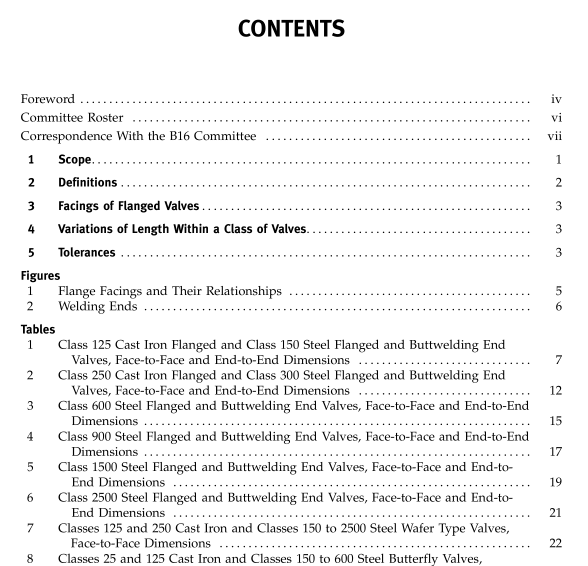

ASME B16.10:2017 pdf free download Face-to-Face and End-to-End Dimensions of Valves

2.4 Buttwelding End Valve Dimensions Forbuttweldingend valves,theend-to-enddimension is the distance between the extreme ends (root faces) of the welding bevels (see Fig. 2). Also see section 4.

2.5 Grooved End Valve Dimensions The end-to-end dimension for grooved end valves is the distance between extreme ends.

2.6 Angle Valves For flanged angle type valves (those in which the ends are at an angle of 90 deg to each other), the center-toface dimension is the distance from the centerline of the port to the extreme end which is the gasket contact surface. For flanged angle type valves in which the gas- ket seating surface is not located at the extreme end and for angle type valves having buttwelding ends, the phrase center-to-end denotes the distance from the cen- terline of the port to the extreme end.

3 FACINGS OF FLANGED VALVES Figure 1 shows facings for flanged ends.

3.1 Facings Normally Furnished

3.1.1 Flat Face. Flanges for Classes 25 and 125 cast iron valves are flat faced.

3.1.2 2 mm (0.06 in.) Raised Face. Flanges for Class 250 cast iron and for Classes 150 and 300 steel, alloy, and ductile iron valves have 2 mm (0.06 in.) raised faces, which are included in the face-to-face (or centerto-face) dimension. When Classes 150 and 300 valves are required with flat faces, either the full thickness of flange or the thickness with the 2 mm (0.06 in.) raised face removed may be furnished, unless otherwise speci- fied by the customer. Users are reminded that removing the 2 mm (0.06 in.) raised face will make the face-to- face dimension nonstandard.

3.1.3 7 mm (0.25 in.) Raised Face. Flanges for Class 600 and higher steel and alloy valves have 7 mm (0.25 in.) raised faces, which are included in the face- to-face (or center-to-face) dimensions.

3.2 Other Standard Facings Table 9 (Table I-9) summarizes data on all flange facings and can be used with Tables 1 through 6 (Tables I-1 through I-6) in calculating face-to-face and end-to-end dimensions of flanged valves having stan- dard facings other than those described in para. 3.1.

3.3 Ring Joint Facings The X dimension given in Table 10 (Table I-10), when added to the face-to-face dimension of a valve having raised face flanges in Tables 1 through 6 (Tables I-1 through I-6), establishes the end-to-end dimension for the valve having flanges with ring joint facings.

4 VARIATIONS OF LENGTH WITHIN A CLASS OF VALVES

4.1 Buttwelding End Valves Tables 1 through 6 (Tables I-1 through I-6) include end-to-end dimensions for valves having buttwelding ends. In many cases, the dimensions are different from those of face-to-face dimensions of flanged valves, as evidenced by the differences between dimensions A and B of the tables. Also see para. 2.4.

4.1.1 Short Pattern. For pressure seal or flangeless bonnet valves having buttwelding ends in Class 600 and higher, the regular end-to-end dimensions shall be equal to the short pattern dimensions shown in Tables 3 through 6 (Tables I-3 through I-6). At the manufacturer’s option, the end-to-end dimensions of these valves may be the same as the face-to-face dimensions of raised face flanged valves.

4.1.2 Long Pattern. For flanged bonnet valves hav- ingbuttweldingends inClass 600 andhigher, the regular end-to-end dimensions shall be equal to the face-to-face dimensions of raised face flanged valves shown in Tables 3 through 6 (Tables I-3 through I-6). At the manu- facturer’s option, the end-to-end dimensions may be the same as the short pattern end-to-end dimensions.

4.2 Narrow, Wide, and Extra Wide Designations Certain butterfly valves are designated narrow, wide, orextra wide for the purpose ofconsolidatinga diversity of manufacturer’s lengths into two or three sets of dimensions for a given size. At the manufacturer’s option, any of the two or three dimensions listed for a size may be used. 5 TOLERANCES 5.1 Straightway Valves A tolerance of ±1.5 mm (±0.06 in.) shall be allowed on face-to-face and end-to-end dimensions of valves of NPS 10 and smaller, and a tolerance of ±3.0 mm (±0.12 in.) shall be allowed for NPS 12 and larger. For exceptions as related to wafer type and butterfly valves,

ASME B16.10:2017 pdf free download