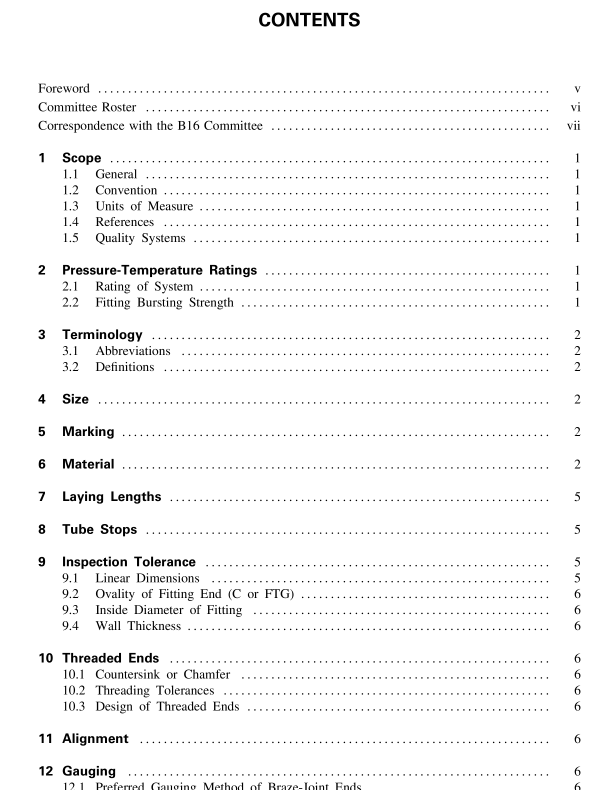

ASME B16.50:2001 pdf free download WROUGHT COPPER AND COPPER ALLOY BRAZE-JOINT PRESSURE FITTINGS

9.2 Ovality of Fitting End (C or FTG) Maximum ovality of the fitting braze-joint end shall not exceed 1% of the maximum diameters shown in Table 3 (Table I3). The average of the maximum and minimum diameters shall be within the dimensions shown in the table.

9.3 Inside Diameter of Fitting The minimum cross-sectional area of the inside diam- eter through the fitting body shall not be less than the theoretical minimum area defined by diameter “O” in Table 3 (Table I3). The out-of-roundness condition of the cross-sectional area shall not exceed the value shown in Table 3 (Table I3). For reducer or adapter fittings, the smallest end diameter shall apply, provided that this diameter does not restrict the other outlets.

9.4 Wall Thickness The minimum wall-thickness shall not be less than shown in Table 3 (Table I3).

10 THREADED ENDS Fitting threads shall be right-hand, conforming to ASME B1.20.1, American National Standard for Pipe Threads, General Purpose (Inch). They shall be taper threads (NPT).

10.1 Countersink or Chamfer All internal threads shall be countersunk a distance no less than one-half the pitch of the thread, at an angle of approximately 45 deg with the axis of the thread. All external threads shall be chamfered at an angle of 30 deg to 45 deg from the axis. Countersinking and chamfering shall be concentric with the threads. The length of threads shall be measured to include the countersink or chamfer.

10.2 Threading Tolerances Tapered pipe threads (NPT) shall be checked by use of plug or ring gauges in either standard or limit types. When gauging internal taper threads, the plug gauge shall be screwed handtight into the fitting. The reference point for gauging internal product-threads depends on the chamfer diameter.

When the internal-chamfer diame- ter exceeds the major diameter of the internal thread, the reference point shall be the last thread scratch on the chamfer cone. Otherwise, when the internal-chamfer diameter does not exceed the major diameter of the internal thread, the reference point shall be the end of the fitting. In gauging external taper threads, the ring gauge shall be screwed handtight on the external thread. On the external thread, the ring gauge shall be flush with the end of the thread. Tolerance for an internally threaded end having an internal shoulder shall be from the gauge reference point (notch) to one turn small. Tolerance for an internally threaded end without a shoulder, and for an externally threaded end, shall be from one turn small to one turn large.

10.3 Design of Threaded Ends The wrenching section of internally threaded ends shall be polygonal, and the wrenching section of exter- nally threaded ends shall be furnished with either polygon or flats, at the manufacturer’s option. 11 ALIGNMENT The maximum-allowable deviation in the angular alignment of any end from the specified axis position shall be 1 ⁄ 2 deg (1 deg total) (see Fig. 3).

12 GAUGING

12.1 Preferred Gauging Method of Braze- Joint Ends The preferred method of gauging the diameter tolerances for external and internal ends shall be by the use of plain plug and ring gauges designed to hold the product within the limits established in Table 3 (Table 13). Gauge tolerances shall be Class ZM, as defined in ASME B4.4M.

12.2 Optional Gauging Method of Braze-Joint Ends For gauging the diameter tolerance of external and internal ends, the use of direct reading instruments instead of ring and plug gauges as specified in para.12.1 shall be permitted. When gauging the diameters 7 of external and internal ends using direct reading instru- ments, refer to para. 9.2.

ASME B16.50:2001 pdf free download