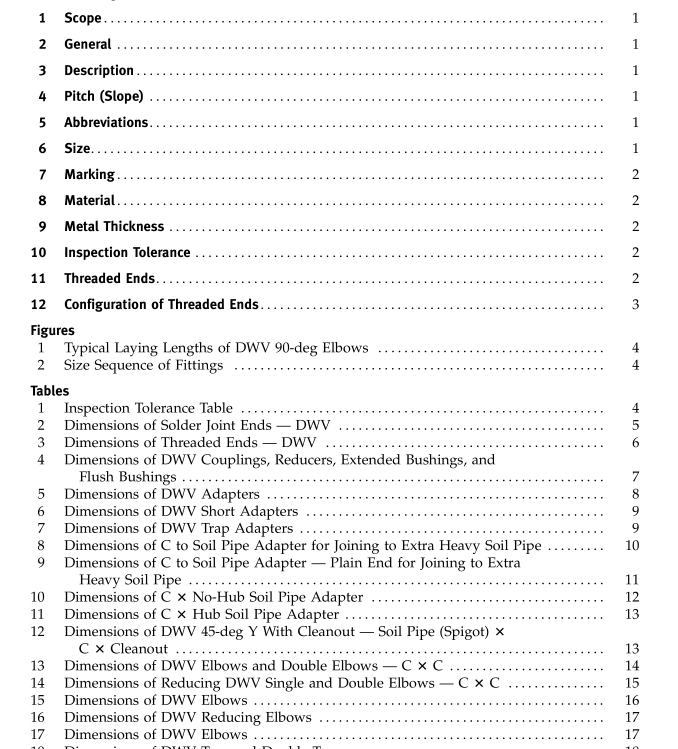

ASME B16.23:2016 pdf free download Cast Copper Alloy Solder Joint Drainage Fittings: DWV

7 MARKING

(a) Each fittingshall be marked permanentlyand legi- bly with the manufacturer’s name or trademark and with “DWV” (to indicate Drain Waste Vent). (b) Vent fittings shall be permanently marked “VENT ONLY” (See Tables 43, 44, I-43, and I-44) and show the manufacturer’s name or trademark in accordance with MSS SP-25. 8 MATERIAL Castings shall be copper alloy produced to meet (a) the requirements of ASTM B62 Alloy C83600; or

(b) the chemical and tensile requirements of ASTM B584 Alloy 83800 or 84400, and in all other respects comply with the requirements of ASTM B62.

9 METAL THICKNESS Dimensional variations will occur in the casting pro- cess. Patternequipment shall be designed to produce the metal thickness given for fittings in Table 2 or Table I-2. Any final fitting metal wall thickness less than 90% of the thickness given in the table is unacceptable.

10 INSPECTION TOLERANCE

10.1 Convention For determining conformance with this Standard, the convention for fixing significant digits where limits (maximum and minimum values) are specified shall be as defined in ASTM E29. This requires that an observed or calculated value be rounded off to the nearest unit in the last right-hand digit used for expressing the limit. Decimal values and tolerances do not imply a particular method of measurement.

10.2 Linear Dimensions DWV fittings covered by this Standard shall conform to the laying lengths specified in Tables 4 through 56 and Tables I-4 through I-56. An inspection tolerance, as shown in Table 1 or Table I-1, shall be allowed on center- to-shoulder, center-to-threaded end, and shoulder-to- threaded end dimensions on all fittings having internal solder (cup) ends; and on center-to-solder end, solder end-to-shoulder, and solder end-to-threaded dimen- sions on all fittings having external solder (fitting) ends. The largest opening in the fitting governs the tolerance to be applied to all openings. The inspection tolerance for laying length dimensions A, B, and C (in Table 4 or Table I-4) shall be double those shown above, except the minus tolerance applied to 2 couplings; dimension A shall not result in a dimension less than 2.3 mm (0.09 in.).

10.3 Ovality Maximum ovality shall not exceed 1% of the maxi- mum diameters shown in Table 2 or Table I-2. The aver- age of the maximum and minimum diameters shall be within the dimensions shown in the table.

10.4 Alignment The maximum allowable variations in the regular alignment of all openings shall be 5 mm/m (0.06 in./ft).

10.5 Gaging of Solder Joint Ends

(a) Standard Gaging Method of Solder Joint Ends. The standard method of gaging the diameter tolerances for male and female ends shall be by the use of plain plug and ring gages designed to hold the product within the limits established in Table 2 or Table I-2.

(b) Optional Gaging Method of Solder Joint Ends. For gaging the diameter tolerance of male and female ends, the manufacturer may use direct reading instruments instead of ring and plug gages as specified in (a). When gaging the diameters of male and female ends, using direct reading instruments, refer to para. 10.3.

11 THREADED ENDS

11.1 General Threaded ends shall conform to the dimensional requirements contained within Table 3 or Table I-3. Fitting threads shall be right-hand, conforming to ASME B1.20.1. They shall be taper threads (NPT) except for slip joint ends, which shall have straight pipe threads (NPSM).

11.2 Thread Dimensions All internal threads shall be countersunk a distance not less than one-half the pitch of the thread at an angle of approximately 45 deg with the axis of the thread. All external threads shall be chamfered at an angle of 30 deg to 45 deg from the axis. This facilitates joint assembly and thread protection. Countersinking and chamfering shall be concentric to the threads. The length of threads specified in all tables shall be measured to include the countersink or chamfer.

11.3 Threading Tolerances Tapered pipe threads (NPT) shall be checked by use of working plug or ring gages either standard or limit types. Gages shall be threaded hand tight. The reference point for gaging internal taper threads, the plug gage, shall be screwed hand tight into the fitting. Internal product threads depend upon the chamfer diameter. When the internal chamfer diameter exceeds the major diameter of the internal thread, the reference point shall

ASME B16.23:2016 pdf free download