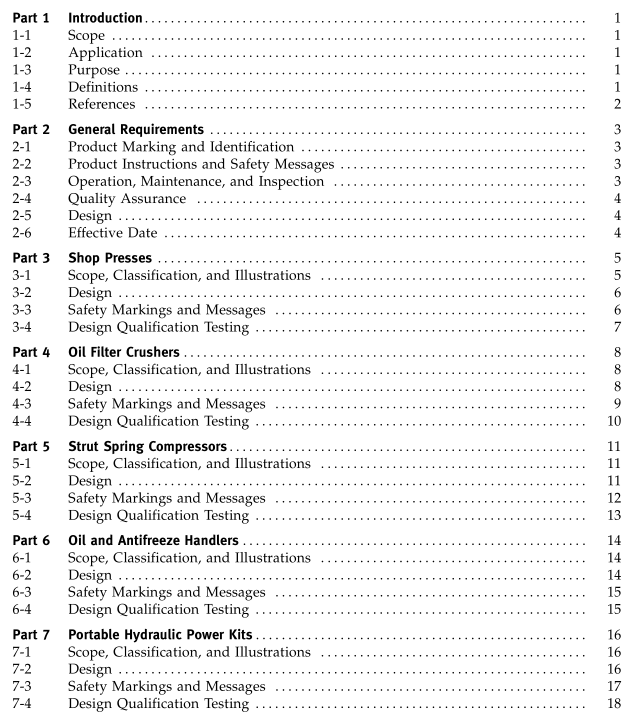

ASME ASP:2010 pdf free download Safety Standard for Automotive Service and Maintenance Products

1-1sCOPE

EThe scope of this Standard is the standardization ofsafety and performances requirements for automotiveservice and maintenance products including, but notlimited to

(a) shop presses

(b) oil filter crushers

(c) strut spring compressors

(d) oil and antifreeze handlers

(e) portable hydraulic power kits

This Standard may include requirements for safetyand health; design, production,construction,mainte-nance, performance, or operation of mechanical,hydraulic,or pneumatically powered equipment; andqualification of personnel.Safety and constructionrequirements for electrical equipment are included inUL 201,”Standard for Safety for Garage Equipment,”and UL 2089,”Standard for Safety for Vehicle BatteryAdapters.” As deemed necessary by this Subcommittee,additional equipment classified as PALD-related equip-ment can be added as the need arises to ensure the safeoperation of the equipment by the end user.

1-2APPLICATION

This Standard applies to the design, construction,marking, operation, maintenance, and owner or opera-tor inspection of the listed automotive service and main-tenance equipment, used during automotive service andmaintenance of components, vehicles, or both. Opera-tion and maintenance instructions in this Standard areintended for general application. The equipment manu-facturer or supplier shall be consulted for specific opera-tion and maintenance instructions.

This Standard does not apply to lifting devices cov-ered under the ASME Standard for Portable AutomotiveLifting Devices (PALD).

1-3PURPOSE

This Standard is designed to

(a) guard against and mitigate injury to workers,andotherwise provide for the protection of life,limb, andproperty by prescribing safety requirements

(b) provide direction to purchasers, owners, employ-ers, supervisors,and others concerned with, or responsi-ble for, its application

(c) guide governmental and other regulatory bodiesin the development, promulgation, and enforcement ofappropriate safety directives

1-4DEFINITIONS

alferafion: any change to an automotive service andmaintenance product (ASMP) other than maintenance,repair, or replacement.

appointed: assigned specific responsibilities by theemployer or the employer’s representative.

approved: accepted as satisfactory by a duly constitutedadministrative or regulatory authority.

ASMP: any one of the various types of automotive ser-vice and maintenance products listed in the scope ofthis Standard.

authorized: approved by a duly constituted administra-tive or regulatory authority.

authorized personnel: persons who have been instructedin the operation or maintenance or both of the ASMPand designated by the owner to use or maintain theequipment.

controls, operating: the mechanisms that must be manipu-lated by the operator to govern the starting, stopping,direction of motion, acceleration, speed, and retardationof the moving member(s) of the ASMP.

cylinder: a means by which force is transmitted to anobject by hydraulic or air pressure. The word “ram” canbe used interchangeably for cylinder. Unless otherwisespecified , these two words are treated as synonyms.designated: selected or assigned by the employer or theemployer’s representative as being competent to per-form specific duties.

electric porver source: a device that utilizes electricity asthe force- or delivery-transmitting medium.

fixed: permanently set in one location and not readilymovable to another work area.

functional damage: any detrimental, permanent deforma-tion of the ASMP’s structure that results in the loss ofsealing capability to its hydraulic or pneumatic compo-nents or both; loss of motion; or failure to meet or exceedthe design qualification limits established in sections3-4,4-4,5-4,6-4, and 7-4.

guard: see definition in para.3-1.4.

hydraulic power source: a device that utilizes hydraulicsas the force- or delivery-transmitting medium.

internal load-limiting device: a device that limits the outputforce of the ASMP.

listed: refers to a product that has been tested,foundcompliant,and approved to a specific standard, andcan be supported by the appropriate documentationconfirming such.

load: the total superimposed force to be overcome bythe ASMP.

nanufacfurer: a company that produces goods for sale.nobile: describes an ASMP that is readily movable fromone work area to another.

OSHA: Occupational Safety and Health Administration,the arm of the U.s. government that establishes rulesand regulations for workplace safety.

overload: a force or volume that exceeds the rated capac-ity of the ASMP.

pneumatic pozver source: a device that utilizes compressedair as the force- or delivery-transmitting medium.

portable: not permanently fixed in one location and ableto be moved from one work area to another.

proof load: a force greater than the rated capacity, appliedcentrally to a work surface as defined by the ASMP’sloading apparatus to confirm the integrity of thestructure.

qualified personnel: individuals with characteristics orabilities gained through training or experience or both,as measured against established requirements or criteria,such as standards or tests that enable them to performa required function or service.

ram: see cylinder.

ASME ASP:2010 pdf free download