ASME N510:2007 pdf free download Testing of Nuclear Air Treatment Systems

1 sCOPE

This Standard covers in-service testing of ASME N509high-efficiency air treatment systems for nuclear powerplants.

1.1 Use of This Standard

This Standard provides a basis for the developmentof test programs and does not include acceptance criteriaexcept where the results of one test influence the per-formance of other tests.Acceptance criteria shall bedeveloped based on the design/ function in accordancewith ASME N509.

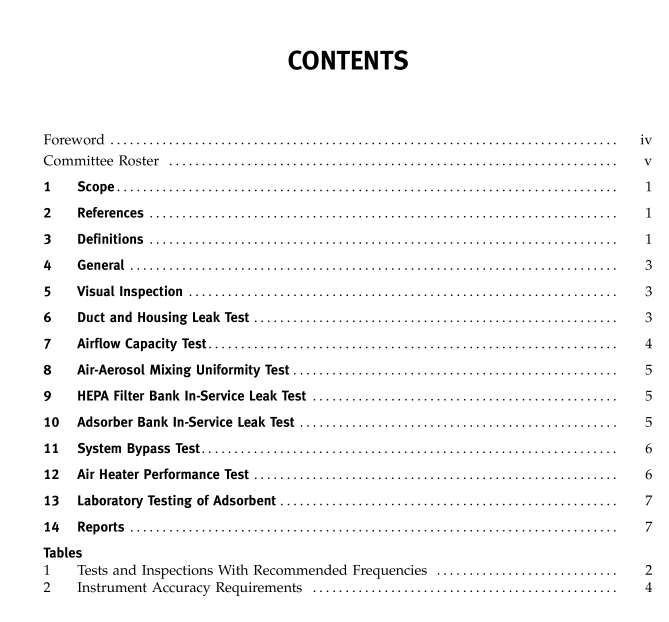

This Standard is arranged so that the user may selectthose portions (tests) that are relevant to their applica-tion. Tests should be performed in the sequence listedin Table 1. Table 1 also lists the recommended minimumfrequency for performing these tests. The user mustspecify which tests shall be performed, and the accept-ance criteria for those tests, in the test program.

1.2 Limitations of This Standard

This Standard covers the in-service (operational) test-ing of installed air treatment systems. This Standardshall be applied in its entirety to systems designed andbuilt to ASME N509 specifications.Sections of thisStandard may be used for technical guidance for testingair treatment systems designed to other criteria.ASME AG-1,Section TA covers the acceptance-testingprogram.

2REFERENCES

The following references supplement this Standardand are part of it to the extent indicated in the text. Theissue (date / revision) of the referenced document notedbelow shall be in effect. If no date is listed, then theissue of the referenced document in effect at the timeof the purchase order shall apply.ASME AG-1 containscode requirements for nuclear air and gas treatmentequipment. These code requirements may be substitutedfor the requirements listed herein.

Industrial Ventilation: A Manual of RecommendedPractice (24th edition)

Publisher: American Conference of GovernmentalIndustrial Hygienists (ACGIH),1330 KemperMeadow Drive, Cincinnati, OH 45240

ANS 3.1-1993,Selection,Qualification, and Training ofNuclear Power Plant Personnel

Publisher: American Nuclear Society (ANS),555 NorthKensington Avenue,LaGrange Park,IL 60526

ASME AG-1,Code on Nuclear Air and Gas TreatmentASME N509,Nuclear Power Plant Air-Cleaning Unitsand Components

ASME N511, Standard for In-Service Testing of NuclearAir Treatment,Heating, Ventilating, and AirConditioning Systems

ASME NQA-1, QualityAssurance ProgramRequirements for Nuclear Facilities

Publisher: The American Society of MechanicalEngineers (ASME),Three Park Avenue,New York,NY 10016-5990; Order Department: 22 Law Drive,P.O.Box 2300,Fairfield, NJ07007-2300

ASTM D 3803-1991,Standard Test Method forRadioiodine Testing of Nuclear-Grade Gas PhaseAdsorbents

Publisher: ASTM International(ASTM), 100 Barr HarborDrive,P.O.Box C700,West Conshohocken,PA19428-2959

Procedural Standards for Testing, Adjusting, andBalancing of Environmental Systems,1998

Publisher: National Environmental Balancing Bureau(NEBB),8575 Grovemont Circle,Gaithersburg, MD20877

HVAC Systems Testing, Adjusting, and Balancing,1993-2

Publisher: Sheet Metal and Air ConditioningContractors’ National Association (SMACNA),4201Lafayette Center Drive, Chantilly,VA 20151-1209

3DEFINITIONS

The definitions provided in this section supplementthose listed in ASME AG-1,Section AA-1000.

activated carbon: an adsorbent of porous structure manu-factured by carbonization of organic material and con-trolled oxidation to increase its microporosity, consistingmainly of elemental carbon in a porous structure.

adsorbent: any solid having the ability to concentrateother substances on its surface.

adsorber: a device or vessel containing adsorbent.

adsorber bank or filter bank: one or more filter or adsorbercells secured in a single mounting frame, or one or moreside-by-side panels poured or packed air treatmentmedia, confined within the perimeter of a duct, plenum,or vault cross section, sometimes referred to as a stage.adsorber cell: a modular container for an adsorbent, withprovision for sealing to a mounting frame, which canbe used singularly or in multiples to build up a systemof any airflow capacity.

aerosol: a stable suspension of particles, solid or liquid,in air.

aerosol detection instrument: an instrument capable ofmeasuring challenge aerosol concentration with a linearrange of at least 1 to 105.

challenge: to expose a filter, adsorber, or other air-clean-ing device to an aerosol or gas of known characteristics,under specified conditions, for the purpose of testing.challenge aerosol: the challenge aerosol used for in-placeleak testing of installed HEPA filter systems.

challenge gas: a gas of known characteristics used forin-place testing of adsorbers.

dioctal phthalate(DOP): a chemical that, in aerosol form,is used to evaluate the efficiency of HEPA filters.

filter: a device that removes matter from a fluid, whichpasses through it.

halide gas detection instrunent: an instrument capable ofdistinguishing halide challenge gas from backgroundand detecting halide gas with a linear range of 1 to 105.high-efficiency particulate air filter (HEPA filter): a dispos-able, extended media, dry type filter enclosed in a rigidcasing that exhibits a minimum efficiency of 99.97%when tested with an essentially monodisperse 0.3 umaerosol.

ASME N510:2007 pdf free download