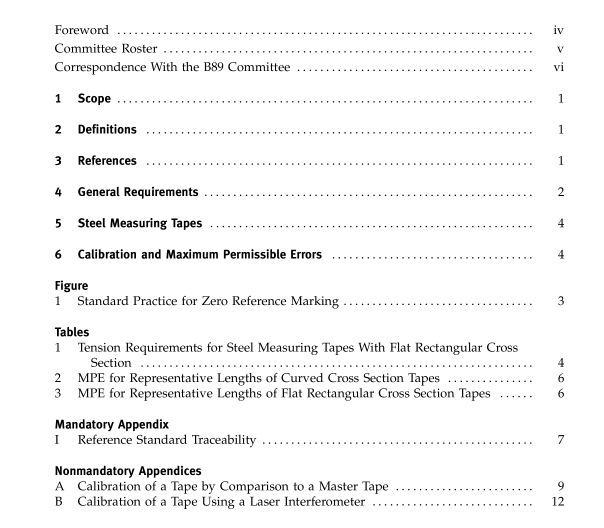

ASME B89.1.7:2009 pdf free download Performance Standard for Steel Measuring Tapes

1 sCOPE

This Standard specifies the requirements for steel mea-suring tapes, with respect to units (SI and U.s.Customary).graduations,numbering,designations, andaccuracy requirements.

DEFINITIONS

accuracy: closeness of agreement between a measuredquantity value and a true quantity value of a measurand.Accuracy is a qualitative concept. (VIM 2.13)

graduuations: marks or lines perpendicular to the edge ofa measuring tape denoting increments of measure.

intermediate graduation: a graduation mark denoting anincrement of measure that falls between the major andthe minor graduations (e-g., inch or centimeter).

major graduation: a graduation mark denoting the largestincrement of measure (e.g., feet or meter).

maxinmunm perrmissible errors (MPE): extreme value of mea-surement error, with respect to a known reference quan-tity value, permitted by specifications or regulations fora given measurement, measuring instrument,or measur-ing system. (VIM 4.26)

minor graduation: a graduation mark denoting the small-est increment of measure (e.g-, fraction of an inch, deci-mal inch, or millimeter).

plumb bob: when used with a measuring tape, a weightwith a tapered or flat tip on the bottom that is suspendedfrom the tape.

tension: a force that tends to stretch or elongate some-thing, or a measure of such a force.

NOTE: The measure of force in the U.S. Customary system is thepound (Ibf); the measure of force in the Sl system is the newton(N).Traditionally,the tension (a force) has been referred to in unitsof pounds and kilograms. Pound (or pound-force) is proper. In theSl system of units, the kilogram is the unit of mass and the newtonis the unit of force.In this Standard, the tension for tapes graduatedin Sl units is specified in kilograms, in order to maintain continuityof reference to master tape calibration data.The correspondingforce in newtons is equal to the applied mass in kilogramsmultiplied by the acceleration due to gravity, g. By convention,g = 9.80665 m/ s2 exactly. Thus, the force exerted on a tape by ai kg load is 9.80665 N. For highest accuracy, the local value of gshould be used.

calidity conditions: the set of values or range of valuesof the relevant influence quantities, e.g., environmentalconditions, under which the performance specificationsare valid.

zero reference mark: the location from which all graduationand numbering of the measuring tape is dimensioned.

3REFERENCES

3.1 Normative References

lf the American National Standard Institute (ANSI)and ISO standards referred to in this document aresuperseded by a revision, the revision shall apply.IEEE/ASTM Sl 10-2002,Standard for Use of theInternational System of Units (SI): The Modern MetricSystem

Publisher: Institute of Electrical and ElectronicsEngineers,Inc.(IEEE),445 Hoes Lane,Piscataway,NJ 08854-4141 (www.ieee.org)

ISO 1:2002,Geometrical Product Specifications (GPS)—Standard Reference Temperature for GeometricalProduct Specification and verification

ISO/IEC Guide98-3:2008,UncertaintyofMeasurement — Part 3: Guide to the Expression ofUncertainty in Measurement (GUM:1995)

Publisher: International Organization forStandardization (Iso),1 ch. de la Voie-Creuse, Casepostale 56,CH-1211, Geneve 20,Switzerland / Suisse(www.iso.org)

JCGM 200:2008,International Vocabulary ofMetrology — Basic and General Concepts andAssociated Terms (VIM)

Publisher: Bureau International des Poids et Mesures(BIPM),Pavillon de Breteuil,92312 Sevres cedex,France (www.bipm.org)

3.2 Additional References

API MPMS 3.1A2005,Manual of PetroleumMeasurement Standards Chapter 3 -Tank GaugingSection 1A —Standard Practice for the ManualGauging of Petroleum and Petroleum Products

Publisher: American Petroleum Institute (API),1220 L Street,NW,Washington,DC 20005-4070(www.api.org)

ASME B89.6.2,Temperature and Humidity Environmentfor Dimensional Measurement

ASME B89.7.3.1-2001,Guidelines for Decision Rules:ConsideringMeasurement UncertaintyinDetermining Conformance to Specifications

ASME B89.7.5-2006,Metrological Traceability ofDimensional Measurements to the SI Unit of Length,Technical Report

ISO/IEC 17025:2005,General Requirements for theCompetence of Testing and Calibration LaboratoriesPublisher:Internationalorganization forStandardization (ISO), 1 rue de Varembe,Case Postale56,CH-1211,Geneve 20,Switzerland / Suisse(www.iso.org)

NIST SP 811 2008,Guide for the Use of the InternationalSystem of Units (SI)

Publisher: National Institute of Standards andTechnology (NIST),100 Bureau Drive, Gaithersburg,MD 20899-1070 (www.nist.gov)

NOTE:ASME B89documentsmay befound athttp:f / catalog.asme.org,/ hame.cfm?Search B89

GENERAL REQUIREMENTS

All steel measuring tapes covered by this Standardshall conform to the requirements in paras. 4.1through 4.9.

4.1 Straight and Parallel

Steel measuring tapes shall be made so that whenstretched out on a flat surface the edges are nominallystraight and parallel.

4.2 Ease of Reading

All steel measuring tapes shall be clearly marked tofacilitate easy and correct reading.

4.3 Background

The graduations and numbering shall be in sharpvisual contrast with the background.

4.4Compatibility

There shall be compatibility between the legibility ofgraduations and the size and form of numbers, whenrelated to the distance at which the measuring tape isnormally read.

4.5 Measurement Units

Unit names and symbols displayed on metricmeasuring tapes covered by this Standard shall be con-sistent with IEEE /ASTM S1 10-2002.

ASME B89.1.7:2009 pdf free download