ASME B16.24:2006 pdf free download Cast Copper Alloy Pipe Flanges and Flanged Fittings Classes 150, 300, 600, 900, 1500, and 2500

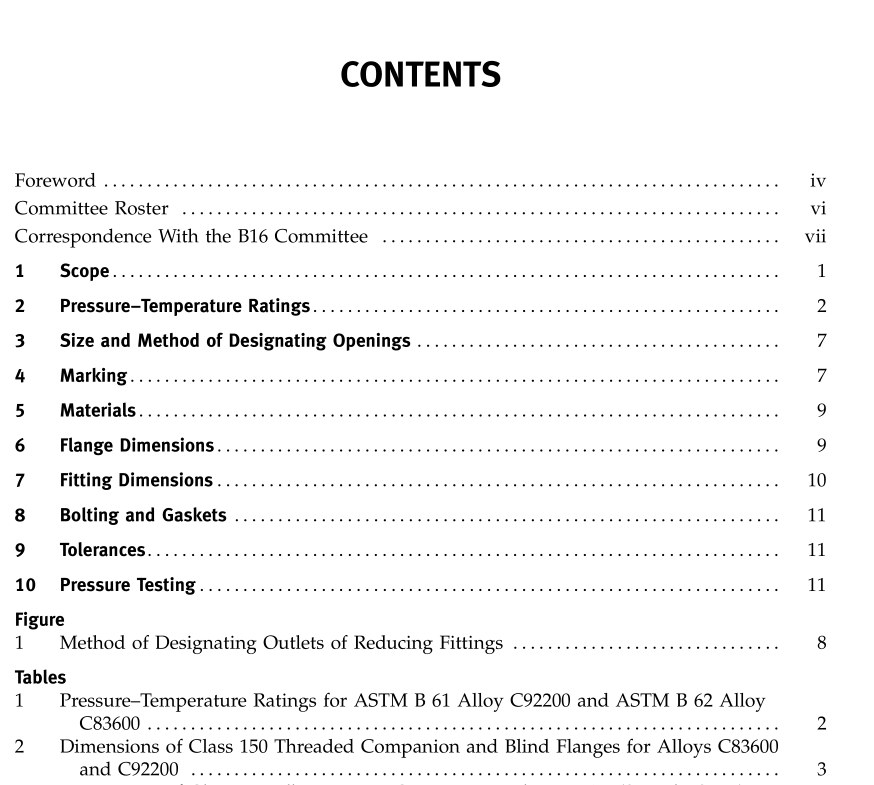

3 SIZE AND METHOD OF DESIGNATING OPENINGS

3.1 Regular Flanges or Fittings The size of a regular flange or fitting is identified by the corresponding nominal pipe size (NPS).

3.2 Reduced Fittings Reduced fittings shall be designated by the size of the openings in their proper sequence as indicated in Fig. 1.

4 MARKING

4.1 General Except as modified herein, flanges and flanged fittings shall be marked as required in MSS SP-25.

4.1.1 Name. The manufacturer’s name or trademark shall be applied.

4.1.2 Material. All flanges and flanged fittings shall be marked with the ASTM specification number. In addition, the grade identification symbol ‘‘952’’ is required for flanges cast to ASTM B 148.

4.1.3 Rating Class. Numerals shall be applied giving the pressure rating class for which the product is designed.

4.1.4 Designation. The designation ‘‘B16’’ shall be applied, preferably located adjacent to the Class designation, to indicate conformance to this Standard.

4.1.5 Size. The nominal pipe size shall be applied but may be omitted from reducing flanges and reducing flanged fittings. 5 MATERIALS 5.1 General Products covered by this Standard shall be made of castings produced to the requirements of para. 5.2 or 5.3.

5.2 Flanges Flanges shall be in accordance with one of the material requirements listed below.

5.2.1 Alloy C83600. Castings shall meet the re- quirements of ASTM B 62.

5.2.2 Alloy C92200. Castings shall meet the re- quirements of ASTM B 61. 5.2.3 Alloy C95200. Castings shall meet the re- quirements of ASTM B 148 and the additional require- ments listed below.

5.2.3.1 Ordering Information. Ordering infor- mation shall include tests on each lot and the form of the test bar. 5.2.3.2 Sampling. The sample for chemical analysis shall be taken from the test bar casting or other casting sample in such a manner as to be represen- tative of each casting lot. 5.2.3.3 Test Bars. A minimum of three test bars shall be poured from each lot of cast metal.

5.2.3.4 Weld Repair Approval. A flange cast- ing shall not be repaired, plugged, welded, or burned- in unless permission from the user of the flange has been previously secured. This will be requested of the user upon the manufacturer’s determination that casting defects are such that after the approved repair, the usefulness and the strength of the casting will not be impaired.

5.2.3.5 Weld Repair. Preparation for repair welding shall include inspection to ensure complete removal of the defect. Repairs shall be made utilizing welding procedures qualified in accordance with Section IX of the ASME Boiler and Pressure Vessel Code. Repair welding shall be done by welders or welding operators meeting the qualification requirements of that Code.

5.3 Flanged Fittings Flanged fittings shall be in accordance with one of the material requirements listed below.

5.3.1 Alloy C83600. Castings shall meet the re- quirements of ASTM B 62.

5.3.2 Alloy C92200. Castings shall meet the re- quirements of ASTM B 61.

5.4 Bolting Bolting materials recommended for use with copper alloy flanges and flanged fittings are described in paras. 5.4.1 and 5.4.2 below.

ASME B16.24:2006 pdf free download